Tubería municipal

Las tuberías municipales suelen estar enterradas (en parte aéreas) y deben tener un diseño y trazado uniformes de acuerdo con la planificación urbana. Deben tener características como sistematicidad, ocultación y durabilidad. La calidad de su construcción afecta directamente a la eficacia de las operaciones urbanas y a la calidad de vida de los residentes.

Envíe su consulta hoy mismo

Suministro municipal de tuberías

Las tuberías municipales se refieren a los sistemas de tuberías utilizados para transportar y descargar diversos fluidos (como agua, aguas residuales, agua de lluvia, gas, etc.) en la construcción de infraestructuras urbanas. Las redes de tuberías constituyen la línea vital de las ciudades modernas, ya que sustentan el funcionamiento normal de las ciudades y las necesidades vitales de los residentes. El diseño y la construcción de tuberías municipales deben seguir normas y especificaciones estrictas para garantizar su seguridad, fiabilidad y durabilidad.

Tipos de tuberías municipales

Selección de materiales para tuberías municipales

Existen varios materiales para las tuberías municipales, los más comunes son el polietileno (PE), el polipropileno (PP), etc. Los distintos tipos de materiales para tuberías son adecuados para diferentes escenarios de aplicación. Por ejemplo, las tuberías de PE y PP son cada vez más populares en la ingeniería municipal moderna debido a su excelente resistencia a la corrosión y fácil instalación; mientras que los materiales tradicionales, como las tuberías de hierro fundido y acero, se utilizan más a menudo en ocasiones con mayores requisitos de resistencia y durabilidad.

Puntos clave para la construcción y el mantenimiento de tuberías municipales

Puntos de construcción

1.Excavación de la zanja: Controlar la planitud de la base en función de las características de la tubería. La cimentación en suelo blando requiere colocar una capa de colchón de arena (espesor ≥ 150mm).

2.Conexión de tuberías: Las tuberías de PE se conectan mediante fusión en caliente o fusión eléctrica, y las tuberías de acero se conectan mediante soldadura o brida para garantizar la calidad de la interfaz.

3.Tratamiento anticorrosión: La capa exterior anticorrosión de la tubería de acero debe cumplir las normas de diseño (como el espesor del revestimiento de 3PE ≥ 2,9 mm).

Gestión del mantenimiento

1.Inspección periódica: Utilice la inspección por CCTV, la medición ultrasónica del espesor y otras tecnologías para evaluar el estado interno de la tubería.

2. Desarenado y dragado: Las tuberías de aguas pluviales deben desarenarse al menos una vez al año, y el ciclo de desarenado de las tuberías de aguas residuales debe determinarse en función del caudal y la calidad del agua.

3.Respuesta de emergencia: Establecer un sistema de información geográfica (SIG) de la red de tuberías para localizar rápidamente los puntos de avería; reservar suministros de emergencia (como materiales de taponamiento y equipos de bombeo).

Artículos relacionados

¿Qué es la soldadura por electrofusión de PE?

Los métodos de conexión de tuberías de PE más comunes en la instalación de tuberías incluyen: conexión por fusión térmica, electrofusión...

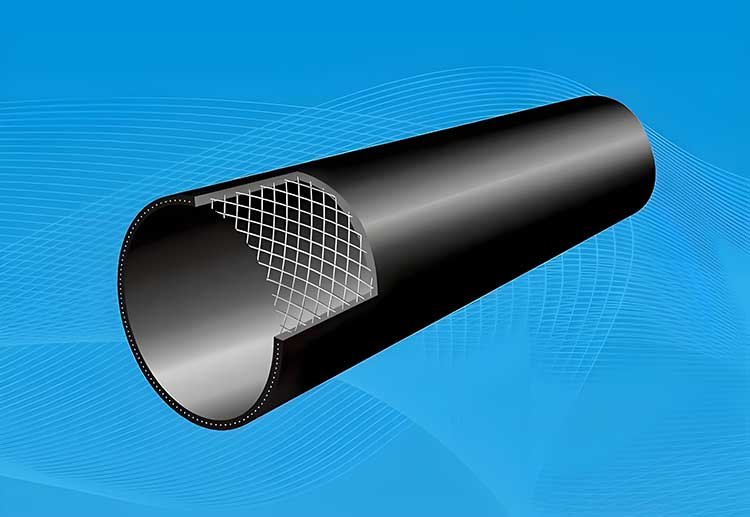

¿Qué son los tubos compuestos de malla metálica de acero PE?

¿Busca plásticos adecuados para el abastecimiento y el saneamiento de aguas municipales? Alambre de acero PE...

Guía completa de la tecnología de tuberías de PE sin zanja

Con la aceleración de la urbanización mundial, la construcción municipal requiere el tendido y...

¿Por qué utilizar tuberías de HDPE en sistemas de drenaje sifónico?

Cuando llueve, de vez en cuando se oye un aterrador gorgoteo procedente de los desagües,...

Designación de especificaciones de tuberías - Guía completa

Las especificaciones de los tubos se indican comúnmente utilizando diversos métodos como DN, pulgada, D, Φ, De,....

Cómo calcular el espesor de la pared de una tubería de PE

Las tuberías de PE se utilizan ampliamente en el suministro y drenaje de agua urbana, gas, telecomunicaciones y energía...