12 Hdpe 파이프

오늘 문의 보내기

12 Hdpe 파이프 제조업체

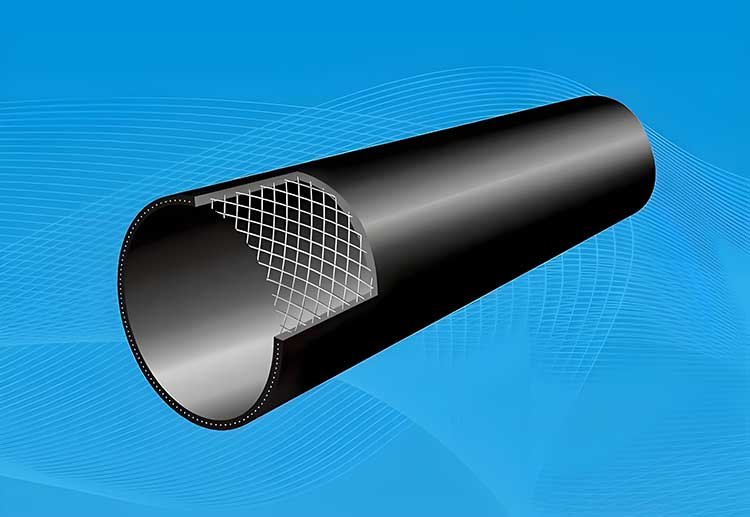

12 HDPE 파이프는 우수한 물리적, 화학적 특성으로 인해 기존의 금속 파이프와 콘크리트 파이프를 대체할 수 있는 고성능 플라스틱 파이프입니다.

12 HDPE 파이프 특징

기계적 특성

높은 인장 강도, 내충격성(23°C에서 낙하 해머 충격 테스트 ≤10% 손상), 링 강성 ≥8kN/m²(배수관용), 기초 침하에 적응 가능;

화학적 특성

내산성(pH 2~13), 내알칼리성, 내염용성으로 대부분의 화학 물질과 반응하지 않으며 주철 및 강관보다 우수합니다;

유체 성능

내벽이 매끄럽고 (거칠기 k = 0.009mm) 유압 마찰이 적고 유속이 동일한 파이프 직경의 콘크리트 파이프보다 30% 더 높으며 스케일링이 쉽지 않습니다;

12 Hdpe 파이프 적용 분야

12 HDPE 파이프는 우수한 성능으로 인해 많은 분야에서 널리 사용되고 있습니다:

도시 엔지니어링:

도시 상수도 및 배수 네트워크, 통합 파이프라인 복도 설치;

수자원 보호 프로젝트:

농지 관개, 저수지 물 이동, 하천 관리;

산업 분야:

화학, 제약 및 식품 공장에서의 자재 운송;

환경 보호 프로젝트:

매립지, 하수 처리장용 파이프 시스템에서 침출수 수거.

연결 및 설치 지점

- 핫멜트 맞대기 용접 시: 가열 온도(보통 190-230℃)와 가열 시간(파이프의 벽 두께에 따라 조정, 12인치 파이프의 가열 시간은 약 5~8분)을 엄격하게 제어해야 합니다. 인터페이스의 균열을 방지하기 위해 냉각 프로세스 중에 파이프를 움직이지 않아야 합니다.

- 전기 융착 연결 시: 특수 전기 융착기를 사용하여 지정된 매개변수(전압, 시간)에 따라 작동해야 합니다. 연결이 완료된 후에는 30분 이상 자연 냉각시켜야 합니다. 냉각 기간 동안에는 어떠한 외력도 허용되지 않습니다.

- 도로나 강과 같은 특수 지역을 횡단할 때는 보호 케이스를 추가해야 합니다. 케이싱의 내경은 HDPE 파이프의 외경보다 100~200mm 커야 하며, 진흙과 모래가 스며들지 않도록 양쪽 끝을 밀봉해야 합니다.

- 고체 입자가 포함된 매체를 이송할 때는 입자 크기를 5mm 이하로 제어하고 농도를 ≤10%로 유지하여 장기 침식 및 파이프 마모를 방지해야 합니다.

- 파이프 라인이 설치되고 수압 테스트를 통과한 후에는 제때 다시 메워야 합니다. 되메우기 재료는 입자 크기가 5mm 이하인 고운 흙 또는 중간 정도의 거친 모래여야 합니다. 돌이나 벽돌과 같은 딱딱한 물체를 사용하는 것은 엄격히 금지되어 있습니다.

관련 기사

PE 일렉트로퓨전 용접이란?

파이프 라인 설치에서 가장 일반적인 PE 파이프 연결 방법에는 열융착 연결, 전기융착...

PE 스틸 와이어 메쉬 복합 파이프는 무엇입니까?

도시 상수도 및 배수에 적합한 플라스틱을 찾고 계십니까? PE 강선...

트렌치리스 PE 파이프 기술에 대한 종합 가이드

글로벌 도시화가 가속화됨에 따라 도시 건설에는 새로운 기반 시설의 설치 및 교체가 필요합니다.

사이펀 배수 시스템에 HDPE 파이프를 사용하는 이유는 무엇입니까?

비가 오면 배수관에서 가끔씩 끔찍한 소리가 들리기도 하는데요, ...

파이프 규격 지정 – 종합 가이드

파이프 규격은 일반적으로 DN, 인치, D, Φ, De 등 다양한 방법으로 표시됩니다.

PE 파이프 벽 두께 계산 방법

PE 파이프는 도시 상수도 및 배수, 가스, 통신, 전력 등에 널리 사용됩니다…