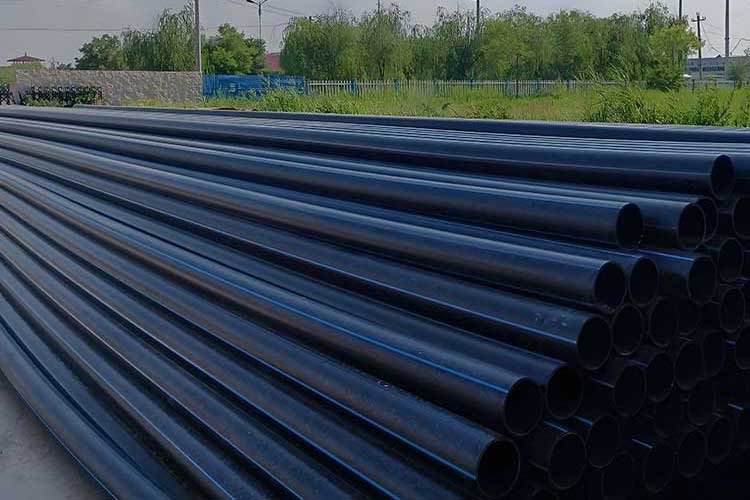

3 Hdpe 파이프

오늘 문의 보내기

3 Hdpe Pipe Manufacturer

3 HDPE pipe is a high-performance plastic pipe that has become a substitute for traditional metal pipes and concrete pipes due to its excellent physical and chemical properties.

3 HDPE Pipe Features

물리적 속성

Flexibility: The bending radius can be ≥25 times the pipe diameter, adapting to foundation settlement or terrain undulations and reducing the number of joints.

Lightweight: The density is about 0.94-0.96g/cm³, and the weight is only 1/8 of that of a steel pipe, with low transportation and installation costs.

화학적 특성

Corrosion resistance: Resistant to acid, alkali, salt solution (pH4-10), and soil corrosion, no additional anti-corrosion treatment is required, and the service life is more than 50 years.

Low permeability: The molecular structure is dense, and the water vapor permeability is less than 0.01g/(m・d), which prevents leakage of media or infiltration of external pollutants.

기계적 특성

High strength: PE100 grade tensile strength ≥26MPa, strong resistance to internal pressure (such as SDR11 pipe pressure resistance 1.0MPa), excellent external pressure impact resistance (-40℃ drop hammer impact pass rate ≥90%).

Thermal Properties

Temperature range: -40℃ to +60℃ for long-term use, +70℃ for short-term use, suitable for temperate to cold climates.

Hot melt: The interface can be integrated through hot melt butt welding and electric fusion connection. The strength is higher than the pipe body and the sealing is reliable.

3 Hdpe Pipe Application Fields

3 HDPE pipe is widely used in many fields due to its excellent performance:

Water supply network:

Replace cast iron pipes to transport domestic water

Chemical industry:

Transport acid and alkali solutions, industrial wastewater; Food industry: transport pure water, beverage raw materials, meet hygiene requirements.

케이블 보호 슬리브:

Protect power and communication cables when laid underground, resist soil stress and insect gnawing.

시공 및 설치 사양

- Hot-melt connection: suitable for straight pipe connection, special hot-melt machine is required, heating temperature is 210±10℃, cooling time is ≥30 minutes, and interface strength reaches more than 90% of the pipe bod

- Electric fusion connection: suitable for pipe fittings (such as tees and elbows), the pre-buried resistance wire is heated and fused by the electric fusion machine, and the voltage (such as 220V) and heating time (about 90-120 seconds) must be strictly controlled.

- Flange connection: used when connecting with metal pipes or equipment, HDPE flange root and rubber sealing ring are required, and the bolt torque is uniform to prevent leakage.

- Construction precautions: When buried underground, the covering depth should be ≥0.7m (≥1.2m for anti-freezing in cold areas), and avoid contact with sharp stones; for hot-melt connections, ensure that the interface is clean to prevent impurities from affecting the strength.

관련 기사

How to choose the HDPE pipes specifications and sizes?

The correct selection of specifications and sizes of HDPE pipes requires consideration of the following…

건물 급수관 시공 기술!

급수관 시스템의 품질은 전반적인 사용 기능에 직접적인 영향을 미치며 ...

주름형 배수관이란 무엇인가요?

골판지 배수관은 얇은 벽의 금속 또는 비금속으로 여러 층으로 만들어진 파이프입니다.....

HDPE 와이어 메쉬 스켈레톤 파이프 대 Hdpe 솔리드 벽 파이프: 차이점은 무엇인가요?

HDPE 와이어 메쉬 파이프 대 솔리드 벽 파이프: 차이점은 무엇입니까 HDPE 와이어 메쉬 ...

도시 배수관의 트렌치리스 수리 방법 살펴보기

도시 배수관의 트렌치리스 수리 방법은 배관을 수리하는 효과적인 방법입니다 ...

빗물을 모으고 활용하는 방법은 무엇인가요?

스펀지 시티는 차세대 도시 빗물 관리 개념으로, 이는 ...