8 Hdpe 파이프

오늘 문의 보내기

8 Hdpe Pipe Manufacturer

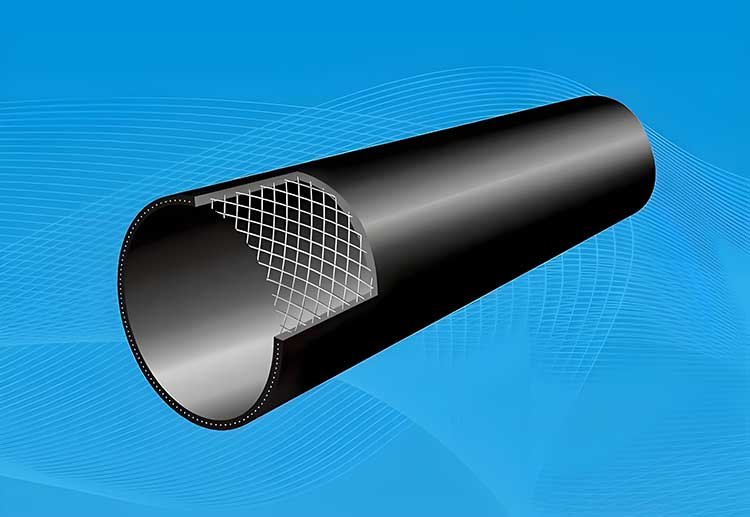

8 HDPE pipe is a high-performance plastic pipe that has become a substitute for traditional metal pipes and concrete pipes due to its excellent physical and chemical properties.

8 HDPE Pipe Features

High strength and toughness

The tensile strength of the pipe is ≥24MPa, the elongation at break is ≥350%, and it has excellent impact resistance. It remains flexible in low temperature environments (-40℃) and is not prone to brittle cracks, making it suitable for laying in complex geological conditions.

화학적 내식성

It has good tolerance to acid, alkali, salt solution and most organic solvents, and does not require anti-corrosion treatment. It can be used to transport corrosive media such as chemical wastewater and industrial waste liquid, and its service life far exceeds that of metal pipes.

Aging and weather resistance

After adding anti-ultraviolet (UV) and antioxidant additives, it can resist long-term ultraviolet radiation when exposed to the outside; the normal operating temperature range is -40℃~60℃, and the short-term temperature resistance can reach 70℃.

8 Hdpe Pipe Application Fields

8 HDPE pipe is widely used in many fields due to its excellent performance:

도시 엔지니어링:

Urban water supply and drainage pipelines, rainwater collection systems, and sewage pipe networks.

산업 분야:

Chemical liquid transportation, mine tailings pipelines, power plant circulating water systems.

Agriculture and Water Conservancy:

Large-scale irrigation pipe networks, reservoir water pipelines, and farmland drainage systems.

Special environment:

buried pipelines in coastal areas (anti-salt spray corrosion), high water level areas (good anti-floating performance).

연결 및 설치 지점

- Butt fusion: suitable for connecting pipes of the same specification, heating temperature 210±10℃, cooling time adjusted according to the pipe diameter (8-inch pipe cooling about 60-90 minutes), no risk of leakage at the interface.

- Electric fusion connection: The electric fusion pipe is fused by electricity, which is easy to operate and suitable for quick installation on site, especially for maintenance scenarios.

- Flange connection: used for transition connection with metal equipment or pipelines, with reliable sealing.

- Laying and backfilling requirements:When laying pipes, avoid excessive bending (allowable curvature radius ≥ 30D, i.e. 6 meters). If turning is required, special elbows or natural bending should be used. Forced bending is strictly prohibited.

- Backfill is divided into three layers: 300mm from the bottom of the pipe to the top of the pipe is filled with medium-coarse sand (compaction coefficient ≥ 93%), 300-500mm is filled with plain soil (remove stones, compaction coefficient ≥ 90%), and above 500mm is backfilled as usual. It is strictly prohibited to use frozen soil, construction waste or crushed stone for direct landfill.

관련 기사

PE 일렉트로퓨전 용접이란?

파이프 라인 설치에서 가장 일반적인 PE 파이프 연결 방법에는 열융착 연결, 전기융착...

PE 스틸 와이어 메쉬 복합 파이프는 무엇입니까?

도시 상수도 및 배수에 적합한 플라스틱을 찾고 계십니까? PE 강선...

트렌치리스 PE 파이프 기술에 대한 종합 가이드

글로벌 도시화가 가속화됨에 따라 도시 건설에는 새로운 기반 시설의 설치 및 교체가 필요합니다.

사이펀 배수 시스템에 HDPE 파이프를 사용하는 이유는 무엇입니까?

비가 오면 배수관에서 가끔씩 끔찍한 소리가 들리기도 하는데요, ...

파이프 규격 지정 – 종합 가이드

파이프 규격은 일반적으로 DN, 인치, D, Φ, De 등 다양한 방법으로 표시됩니다.

PE 파이프 벽 두께 계산 방법

PE 파이프는 도시 상수도 및 배수, 가스, 통신, 전력 등에 널리 사용됩니다…