The most common PE 파이프 connection methods in pipeline installation include: heat fusion connection, electrofusion connection, socket connection, and flange connection. Today, we will discuss the advantages and specific steps of PE electrofusion welding, which is one of the most widely used connection methods for PE pipes.

What is PE Electrofusion Welding

PE electrofusion welding involves fitting an electrofusion pipe fitting onto a pipe or fitting. A resistance wire embedded in the inner surface of the fitting is energized and heats up, generating heat energy to heat and melt the inner surface of the fitting and the outer surface of the pipe to which it is inserted, thus fusing them into one.

Requirements for Electrofusion Welding

1.Dedicated electrofusion welding equipment is required.

2.Open flames are prohibited.

3.When operating in cold climates (below -5 degrees Celsius) and windy conditions, protective measures should be taken or the welding process adjusted.

Advantages of Electrofusion Welding

1.Applicable to all pipe sizes and specifications.

2.Applicable to pipes and fittings of the same grade and material, and also suitable for connecting pipes and fittings of different grades and materials; less affected by environmental or human factors.

3.Low equipment investment and low maintenance costs.

4.Simple and easy-to-master connection operation.

5.Maintains a smooth inner wall of the pipe, without affecting flow rate.

6.High weld reliability.

Specific Steps of Electrofusion Welding

① Cut the pipe with a plastic pipe cutter or a fine-toothed cutter with a chip guide, ensuring the cut surface is perpendicular to the pipe axis. Remove burrs from the inner edges with a knife.

② Clean the surfaces of the pipe to be joined, mark the insertion depth, and scrape off any remaining outer layer.

③ Slide the socket fitting into the spigot end and position it correctly.

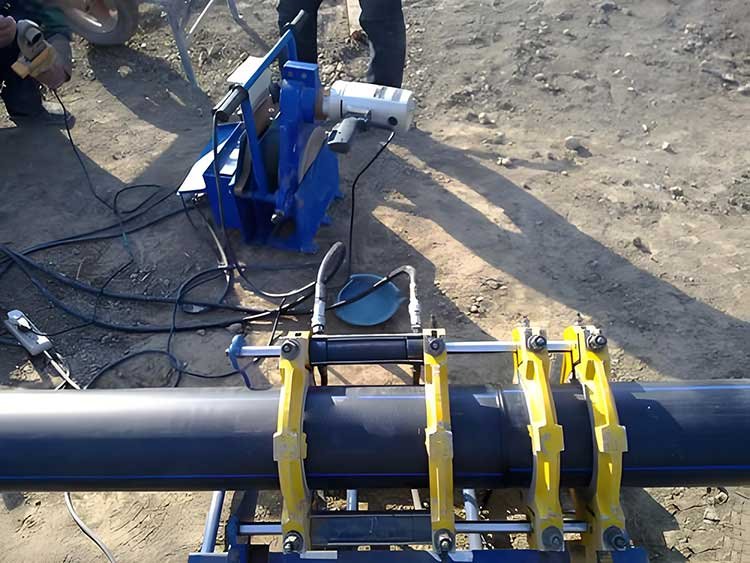

④ Secure and align the positioning clamps, and check that the pipe ends are aligned, ensuring they are on the same axis;

⑤ Set the electrofusion welding machine process parameters and begin welding;

⑥ Check that the welding cycle has been completed correctly;

⑦ During the cooling process, the joint must remain clamped, and sufficient cooling time must be ensured.

⑧ After cooling is complete, release the pressure, loosen the clamps, and remove the connected pipe. Welding is now complete.

자주 묻는 질문

How to determine if a PE electrofusion connection is successful?

I. Visual Inspection

Fitting Deformation: After welding, the fittings should be free of bulges, cracks, or molten material overflow, and the joints should be tight without gaps.

Inspection Hole Status: Some electrofusion fittings have inspection holes. These holes should protrude after welding, indicating sufficient molten material filling; failure to protrude may indicate insufficient welding.

Resistance Wire Status: There should be no resistance wire extrusion at the joint; otherwise, it may indicate over-welding due to excessive heating time or voltage.

II. Sealing Test

Soap Water Test: After the joint cools, apply soap water. No bubbles indicate a good seal; bubbles require re-welding.

Pressure Test: A pressure test verifies the joint’s sealing performance. This test is suitable for high-pressure pipelines (such as gas PE pipes).

How long after PE electrofusion welding can it be tested?

After PE electrofusion welding, it generally needs to cool naturally for more than 2 hours before a seal test can be performed. This time is to allow the welded area to cool and set fully, avoiding inaccurate test results or damage to the joint due to incomplete cooling.

How long after PE electrofusion bonding can backfill be done?

After PE electrofusion welding, it needs to cool for at least 2 hours before backfilling. This time is to allow the welded parts to cool and set fully, avoiding uneven stress on the pipe or loosening of the joint during backfilling due to incomplete cooling.