Municipal pipelines, a crucial component of urban infrastructure, drain rainwater from urban surfaces, provide industrial and domestic water, and prevent water pollution. Basic requirements for pipeline materials include sufficient strength and rigidity, a smooth inner surface to minimize flow resistance, corrosion resistance, adequate sealing, cost-effectiveness, and ease of processing. Let’s take a look at fourteen common municipal pipeline materials.

PCCP Pipe

1.Scope of Application

PCCP pipe is most suitable for large-diameter pressure pipes, meeting the requirements of urban water diversion projects, water supply systems, large-scale sewage pipeline projects, and circulating water pipelines in large thermal and nuclear power plants. The national standard for prestressed concrete cylinder pipes (GB/T19685-2005) has been established.

2.Advantages

① A high-quality new pipe material that combines the advantages of steel pipe (SP) and concrete pipe.

② Lower cost than steel pipe, using 70% less steel than steel pipe.

③ Smooth inner wall, excellent hydraulic performance, and easy installation.

④ More than double the service life of steel pipe.

RMPM Pipe

1.Scope of Application

It has broad prospects as a large and medium-diameter water supply and drainage pipe, and also for use in corrosive soils.

2.Advantages

Glass fiberglass reinforced plastic pipe, as a new type of composite pipe, boasts safety, durability, economy, and comprehensive benefits compared to other pipe materials, earning it considerable attention.

PVC-U Pipe

1.Application

PVC-U pipe is a rigid polyvinyl chloride pipe. Available wall structures include double-wall corrugated pipe, reinforced pipe, flat-wall pipe, and steel-plastic composite wrapped pipe. Steel-plastic composite wrapped pipe is typically joined using an inner sleeve adhesive bonding method. Double-wall corrugated pipe, reinforced pipe, and flat-wall pipe are typically joined using a socket-and-spigot joint and sealed with a rubber ring. For flat-wall pipes with a diameter less than 200 mm, adhesive bonding is often used. Due to its various advantages, PVC-U pipe is widely used in municipal drainage and stormwater pipes, and is easy to install.

2.Advantages

When used as drainage pipe, the concentration of hydrogen sulfide gas in the pipe is significantly higher than that in concrete drainage pipes. PVC-U pipe offers excellent sealing properties against odors. When used as drainage pipe, the energy consumption for its production is only 20% of that of cast iron pipe of the same diameter. Its low cost, aging resistance, excellent thermal insulation, and long service life make it widely used in municipal drainage. The material of PVC-U pipe is relatively brittle and cannot withstand external pressure. Therefore, when the pressure requirement is high, reinforced pipe or steel-plastic composite wrapped pipe with good pressure resistance is used.

Glass ductile iron pipe

1.Scope of Application

Ductile iron pipe is a type of cast iron pipe used for buried water supply pipes.

2.Advantages

Compared to steel pipe, it is cheaper, easier to manufacture, and more corrosion-resistant. Its disadvantages are brittleness and weight. While some data indicates pipe sizes between DN40 and DN80, design manuals only list sizes above DN80. Since there is no change in pipe wall thickness due to nominal pressure, there is no need to specify the nominal pressure level.

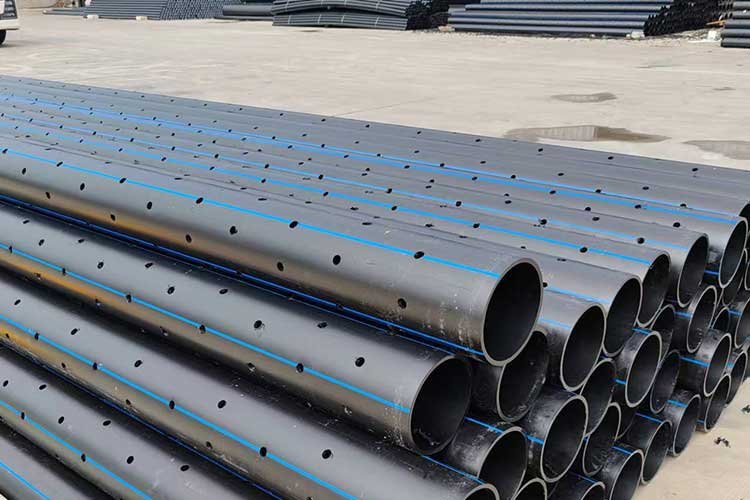

HDPE 배수관

1.Application

HDPE is a highly crystalline, non-polar thermoplastic resin. Its raw form is milky white, with a degree of translucency in thin sections. In water supply and drainage systems, plastic pipes are gradually replacing traditional pipes such as cast iron and galvanized steel pipes, becoming the mainstream pipe material.

2.Advantages

In water supply and drainage systems, plastic pipes are gradually replacing traditional pipes such as cast iron and galvanized steel pipes, becoming the mainstream pipe material. Compared to traditional pipes, plastic pipes offer significant advantages such as light weight, corrosion resistance, low flow resistance, energy conservation, ease of installation, and lower cost, making them a popular choice in the pipeline engineering industry.

FRPP molded pipe

1.Application

Glass fiber reinforced polypropylene (FRPP) pipes are manufactured from glass fiber-modified polypropylene treated with a coupling agent. They are widely used in the petroleum, chemical, power generation, textile, metallurgy, pharmaceutical, papermaking, food, mining, waste disposal, and construction industries, serving as corrosive liquid transport and process piping, earning them a high reputation among users.

2.Advantages

These pipes offer corrosion resistance, high strength, low leakage resistance, low internal resistance, excellent tensile strength, excellent bending resistance, low cost, long service life, and easy installation and maintenance.

RPM Pipe

1.Scope of Application

This pipe features a composite wall structure made of high-strength fiberglass reinforced plastic (FRP) as the inner and outer reinforcement layers, a low-cost quartz sand/resin core layer for increased rigidity, and a tough, acid- and alkali-resistant inner liner and an outer protective layer that meets the requirements of the operating environment.

RPM pipes can be produced using either centrifugal casting or winding processes. They are available in two types: composite pipe, wound pipe, and centrifugally cast pipe. In centrifugal casting, chopped fiber is used; in winding, long fiber is used. The maximum diameter for centrifugally cast RPM pipe is 2400mm, while that for fiber-wound RPM pipe reaches 4000mm. It is a thermosetting plastic pipe.

2.Advantages

① Excellent corrosion resistance

② Lightweight and high strength, easy installation

③ Smooth surface, high flow capacity

④ Excellent low-temperature resistance and thermal insulation

HDPE steel belt reinforced spiral corrugated pipe

1.Scope of Application

HDPE steel-reinforced spiral corrugated pipe, commonly known as steel-belt pipe, is a large-diameter, high-strength drainage and sewage pipe. It utilizes U-shaped steel belts laminated to PE, significantly improving hoop stiffness without increasing cost. At the same weight, it boasts significantly greater strength than spiral and carat pipes, effectively addressing a range of issues, including heavy loads.

2.Advantages

The layers are laminated while the plastic is still molten; unlike spiral pipe (hollow-wall pipe), which is formed through a secondary melt process, each layer is fully bonded and highly durable.

The steel belt surface undergoes a special pretreatment to enhance the steel’s corrosion resistance and the bond between the steel and plastic, improving peel strength. The pipe is wound while the plastic is fully molten, resulting in a robust and reliable overall structure. The specialized materials and processes employed address both corrosion protection and adhesion between the steel and PE, ensuring a service life comparable to pure plastic pipes, exceeding 50 years.

The pipe can be joined securely using electric fusion, heat shrink tape, internal and external extrusion welding, or a combination of these. Reliable connections can make the pipeline leak-free.

HDPE Carat Pipes

Advantages

The pipes are connected using both socket-type electric fusion and throttle-type socket-type connections, with socket-type electric fusion being preferred to ensure the overall resistance of the pipe. It is convenient, safe, and leak-free, and has long been widely used worldwide.

HDPE wire mesh skeleton

1.Application

Steel mesh reinforced plastic composite pipe is a new type of improved steel-reinforced plastic composite pipe. This type of pipe is also known as SRTP pipe. This new type of pipe is made of a high-strength, plasticized steel mesh frame and thermoplastic polyethylene. The steel wire mesh serves as the polyethylene pipe’s reinforcement. High-density polyethylene (HDPE) is used as the matrix, and a high-performance HDPE-modified adhesive resin tightly bonds the steel wire frame to the inner and outer HDPE layers, resulting in an excellent composite finish. Because the high-strength steel wire reinforcement is encased in a continuous thermoplastic, this composite pipe overcomes the shortcomings of both steel and plastic pipes while retaining their respective advantages. It is a high-performance new type of pipe widely used in oil fields, power plants, chemical and petrochemical enterprises, water companies, municipal gas, and seawater pipelines.

2.Advantages

Steel mesh reinforced plastic composite pipe utilizes high-quality materials and advanced production processes, resulting in higher pressure resistance. The composite pipe also exhibits excellent flexibility, making it suitable for long-distance buried water and gas pipeline systems. The fittings used for the wire mesh reinforced polyethylene composite pipe are polyethylene electrofusion fittings. During connection, the heating element within the fitting fuses the outer plastic layer of the pipe with the inner plastic layer of the fitting, reliably connecting the pipe and fitting.

HDPE double wall corrugated pipe

1.Application

This type of pipe is made from high-density polyethylene (HDPE) and is produced through a twin-extrusion process. The result is a smooth inner wall with an annular corrugated outer wall. It is widely used in municipal sewage and drainage systems.

2.Advantages

HDPE double-wall corrugated pipe offers excellent flexibility, light weight, high pressure resistance, corrosion resistance, aging resistance, and a long service life.

PP double-wall corrugated pipe

1.Product Introduction

PP double-wall corrugated pipe has the same structure as common PE double-wall corrugated pipe. It is made from modified polypropylene and extruded in one step using internal and external extruders. The pipe features a smooth inner wall and sinusoidal corrugations on the outer wall. The inner and outer walls are hollow and tightly fused together to form a ring-shaped structure.

2.Product Specifications

The maximum diameter available internationally is DN1800mm. Currently, domestic production reaches up to DN1200mm, but sizes generally range from DN200mm to DN800mm.

3.Product Series

Data indicates that the hoop stiffness of PP double-wall corrugated pipe can reach SN14. Domestically, four series are available: SN4, SN8, SN10, and SN12.5.

결론

The rational selection of municipal pipeline materials is not only a matter of engineering and technical expertise but also a crucial component of a city’s sustainable development strategy. Only by adhering to the principles of “adapting to local conditions, selecting materials based on needs, prioritizing quality, and prioritizing environmental sustainability” can we truly build a safe, efficient, intelligent, and sustainable urban underground infrastructure network, providing solid support for high-quality urban development.