Знакомы ли вы с кабелями ПНД, которые обычно используются в сантехнике? Они называются электрическими ПНД-каналами. Они имеют различные свойства и сферы применения, но зачем они вам нужны?

В этом руководстве мы рассмотрим основы, которые вы должны знать о кабелепроводах из ПЭВП. Мы уверены, что это руководство поможет вам сделать осознанный выбор при покупке пластиковых труб.

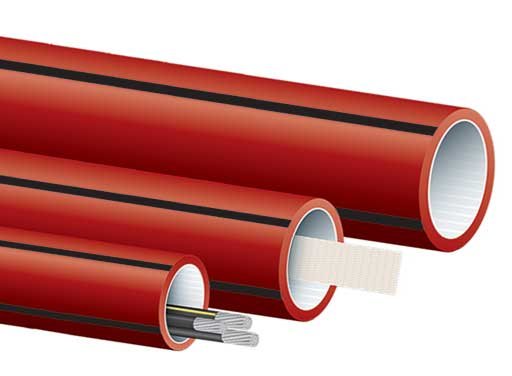

что такое трубопровод hdpe

Трубопровод из ПНД - это пластиковая труба широко используется во многих областях. Он обладает такими характеристиками, как коррозионная стойкость, малый вес и высокая прочность.

Преимущества кабелей из ПНД

Преимущества кабелепровода из ПНД заключаются в следующем:

1. отличная химическая стойкость

ПНД обладает высокой устойчивостью к большинству кислот, щелочей, солей и других химических веществ, не ржавеет и не корродирует. Он идеально подходит для транспортировки агрессивных жидкостей и работы в жестких химических средах.

2.Отличная гибкость и ударопрочность

Трубопровод из ПНД обладает отличной гибкостью и может выдерживать определенные изгибы, просадку грунта и вибрацию. Он также обладает отличной сейсмостойкостью и не поддается внешнему воздействию.

3.Легкий вес, простота транспортировки и установки

По сравнению с металлическими или бетонными трубами, трубы из ПНД имеют меньшую плотность и вес, что значительно снижает транспортные и строительные расходы и повышает эффективность монтажа.

4.Безопасное и надежное соединение без риска утечки

Используя технологию соединения горячим расплавом или электроплавлением, интерфейс и труба являются единым целым. Прочность соединения даже выше, чем у самой трубы, что полностью устраняет проблему протечек. Это особенно подходит для систем с высокими требованиями к герметичности, таких как водоснабжение и газоснабжение.

5.длительный срок службы

При нормальных условиях эксплуатации срок службы трубопроводов из ПЭВП может достигать более 50 лет, при низких эксплуатационных расходах и высокой комплексной экономической выгоде.

Области применения трубопроводов из ПНД

Как правильно выбрать кабелепровод из ПНД

При выборе кабелепровода из ПНД следует руководствоваться следующими критериями:

Состав материала

- В основном смола полиэтилена высокой плотности (HDPE), следует обратить внимание на добавки (например, модификация углерода для улучшения антивозрастных свойств).

Жесткость кольца

- Силовые трубы должны быть ≥SN8, дренажные трубы должны быть ≥SN4

Способ подключения

- Силовые трубы обычно соединяются с помощью раструбных резиновых уплотнений, а дренажные трубы могут соединяться с помощью электроплавки или горячего расплава.

Удобство строительства

- Большая длина одного рулона (например, 200 м/рулон) позволяет уменьшить количество стыков и повысить эффективность. Легкая конструкция удобна для переноски и подходит для работы в узком пространстве.

Ударопрочность/низкая температура окружающей среды

- Выбирайте трубы из ПНД с хорошей гибкостью, чтобы избежать хрупкого растрескивания

Заключение

Трубопроводы из ПНД - это всего лишь трубы, но они играют важную роль в определении их эффективности.

Чтобы встать на правильный путь эффективного строительства, всегда сначала выбирайте кабелепровод ПНД, который отвечает вашим техническим требованиям, а затем выбирайте кабелепровод ПНД, который соответствует вашему бюджету.