Труба з ПНД сітки проти суцільностінної труби: У чому відмінності

Труби з ПНД та суцільностінні труби - це труби, які широко використовуються в комунальному господарстві. Деякі виробники можуть мати труднощі з їх розрізненням через схожість назв.

Дійсно, між ними є певні відмінності. Але як їх розрізнити? Як застосувати цю інформацію до свого бізнесу?

У цій статті ви дізнаєтеся більше про труби з ПНД та суцільностінні труби

Що таке каркасна труба з дротяної сітки ПНД та суцільностінна труба

Каркасна труба зі сталевого дроту ПНД - це новий тип вдосконаленої сталевої каркасної пластикової композитної труби, яку також називають трубою SRTP. В якості сировини використовується високоміцний пластифікований каркас із сталевого дроту та термопластичний поліетилен, в якості армування каркасу поліетиленової пластикової труби - сітка із сталевого дроту, в якості матриці - поліетилен високої щільності, а в якості основи - високоефективна модифікована адгезивна смола з ПНД для щільного з'єднання каркасу із сталевого дроту з внутрішнім та зовнішнім шарами поліетилену високої щільності, завдяки чому він має чудовий композитний ефект та відповідні переваги сталевої та пластикової труб.

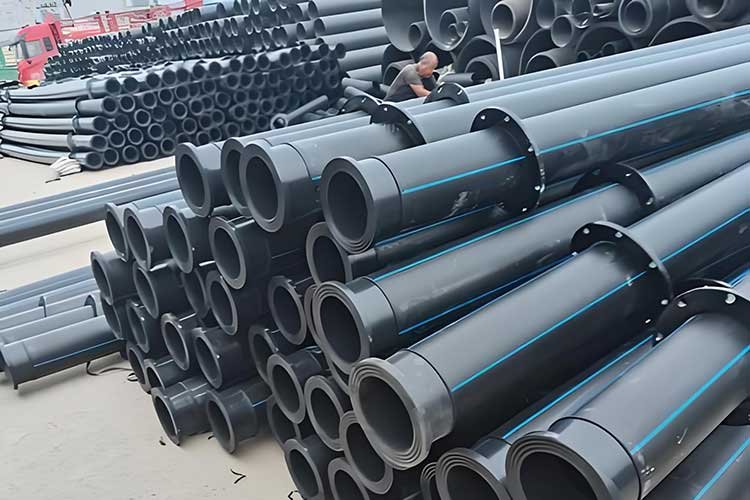

Суцільностінні труби ПНД виготовляються з поліетилену високої щільності в якості основної сировини. Він має одношарову структуру, відмінну корозійну стійкість, хімічну стійкість, стійкість до ультрафіолету і низьку проникність.

Простіше кажучи, композитна труба з каркасом з дротяної сітки ПНД має всередині сталевий дріт.

Допустимий тиск

На несучу здатність суцільностінних труб ПНД в основному впливають міцність і товщина стінок самого матеріалу. Загалом, труби ПНД зазвичай використовуються для систем середнього та низького тиску, таких як водопровід, дренажні системи тощо.

Композитна труба зі сталевого дротяного каркаса ПНД може витримувати більш високий тиск завдяки внутрішній сталевій сітці, що підтримує каркас. Тому вона зазвичай використовується в системах, що вимагають більш високої несучої здатності, таких як транспортування природного газу, транспортування агресивних рідин і т.д. Крім того, він також має сильну стійкість до розтягування, вигину та удару, його нелегко деформувати та розірвати, і він може адаптуватися до вимог транспортування в різних складних умовах.

Підключення

Найпоширеніші методи зварювання суцільностінних труб з ПНД включають термоплавке з'єднання та електроплавке з'єднання, серед яких частіше використовується термоплавке з'єднання. Термоплавке з'єднання полягає в нагріванні труби та з'єднання, щоб розплавити їх, потім швидко з'єднати та охолодити, щоб утворилося міцне з'єднання.

Найпоширенішими методами з'єднання каркасних композитних труб зі сталевої дротяної сітки ПНД є електричне з'єднання плавленням та фланцеве з'єднання. Серед них частіше використовується електричне з'єднання плавленням, яке повинно використовувати спеціальну [електричну плавку]. Електричне з'єднання полягає у вставці композитної труби всередину електронагрівальної труби, нагріванні попередньо закопаної електронагрівальної труби, спочатку розплавленні внутрішньої стінки труби з утворенням розплаву, а потім розплавленні її, розширенні та заповненні зазору в трубі до утворення розплаву на зовнішній стороні труби.

Сфери застосування

Суцільностінні труби з ПНД в основному підходять для застосування в системах середнього та низького тиску, таких як муніципальні трубопроводи водопостачання та водовідведення, газопроводи, сільськогосподарські та лісогосподарські зрошувальні системи тощо.

Композитна труба з каркасом з дротяної сітки ПНД в основному використовується для транспортування в умовах високого тиску або в складних умовах, таких як нафтогазові родовища, електростанції, хімічні заводи, нафтохімічні компанії, водопровідні станції, зовнішній протипожежний захист та інші галузі промисловості.

Вартість

Собівартість виробництва суцільностінних труб з ПНД відносно низька, але термін їхньої служби в суворих умовах, таких як висока температура, високий тиск і знос, короткий, і вони потребують частого технічного обслуговування і заміни.

Вартість виготовлення каркасної композитної труби з дротяної сітки ПНД відносно висока, але вона має тривалий термін служби і низькі витрати на обслуговування, і може стабільно працювати протягом тривалого часу.

Висновок

Композитні труби зі сталевим сітчастим каркасом з ПНД мають відмінні експлуатаційні характеристики в певних специфічних сферах завдяки своїй особливій структурі сталевого каркаса, наприклад, в інженерних проектах, які вимагають підвищеної міцності, здатності витримувати більший тиск і більшої довговічності. Суцільностінні труби з ПНД більш поширені в деяких легких і простих в монтажі сферах, таких як водопровідні та дренажні системи.