When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes, even in houses with good soundproofing. This is due to gravity-fed drainpipes. When the water volume is large enough, gravity creates high pressure at the drainpipe inlet, preventing the water from falling and forcing it to fall into the pipe carrying a large amount of air. These air bubbles, carrying the water flow, strongly rub against the pipe walls, resulting in a loud noise. Simultaneously, because the water flow is constantly affected by the pressure from above, the flow rate is extremely slow.

What is a siphon drainage system

siphon drainage system is a device that utilizes the siphon principle to achieve highly efficient drainage, particularly suitable for rooftop drainage of large buildings such as airports and stadiums. It uses negative pressure within the pipes to quickly expel rainwater, making it more efficient and space-saving than traditional gravity drainage.

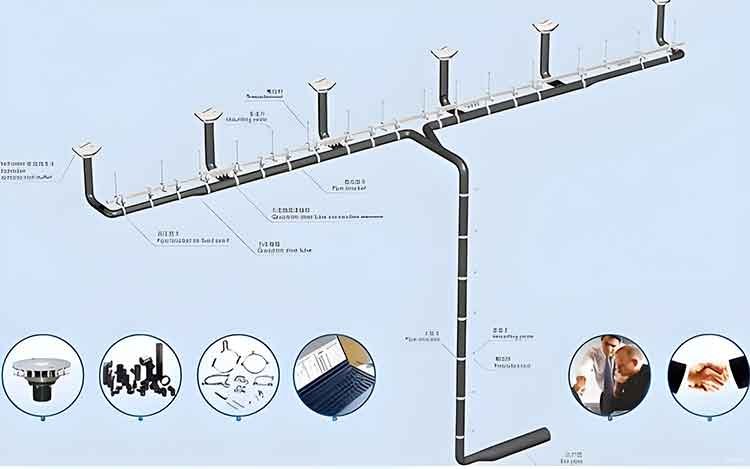

Simply put, its core principle is the siphon effect: when rainwater enters the system through a specially designed rainwater hopper, air is isolated, creating a full-pipe flow and generating negative pressure, which rapidly draws the rainwater out. The system typically consists of anti-vortex rainwater hoppers, suspended pipes, risers, and buried pipes, and is often made of impact-resistant HDPE, with a lifespan of up to 50 years.

Features of siphon drainage system

In the early stages of rainfall, if the accumulated rainwater on the roof does not exceed the designed rainfall height of the siphon rainwater hopper, the drainage method of the entire siphon drainage system is the same as that of the gravity drainage system.

Once the rainwater height on the roof exceeds the designed rainfall height of the siphon rainwater hopper, a siphon effect will occur in the siphon system pipes, and the drainage pipes in the system will be in a full-flow state. At this time, the water in the pipes flows at high speed, and the rainwater on the roof is discharged to the outside at a high flow rate under the suction effect of negative pressure in the pipes.

Advantages of HDPE pipes

It can be connected by butt welding and capacitor welding, which facilitates the formation of a closed seepage prevention system. Especially when laying pipes along trenches, it can reduce the amount of trench excavation and the amount of fittings used.

HDPE pipes are lightweight and easy to install.

Strong wear resistance and compressive strength

HDPE pipes have extremely strong chemical corrosion resistance and are suitable for transporting sewage, natural gas, coal gas, and other substances.

It has a long service life, exceeding nearly 50 years.

Висновок

In a siphon drainage system, the discharge capacity of the drain pipe is significantly greater than that of a gravity drainage system with the same diameter pipe.

For the same volume of rainwater, the impact force of the water on the pipe walls in a siphon drainage system is much greater and stronger.

Therefore, siphon pipes withstand negative pressure, requiring exceptionally high pipe toughness. Ordinary ПЕ труби are insufficient to meet the pressure requirements of siphon drainage systems. Specialized HDPE pipes and fittings must be used.

ЧАСТІ ЗАПИТАННЯ

How is a siphon drainage system installed?

Installing a siphon drainage system does require some technical expertise. Let me outline the key steps and points to give you a clear understanding.

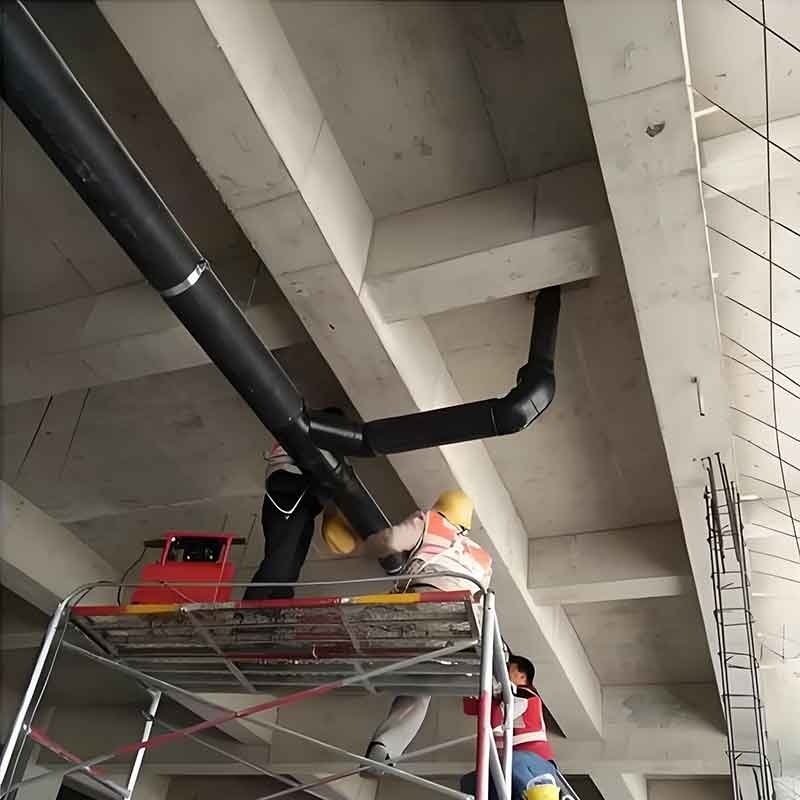

The core process generally consists of these steps: construction preparation → pipe prefabrication → suspension bracket installation → riser installation → buried pipe installation → system water filling test. Each step has its own requirements. For example, pipe connections must use hot-melt welding, the suspension bracket must be fixed to a load-bearing structure, and the verticality error of the riser cannot exceed 3mm.

What tools are needed to install a siphon drainage system?

I. Mechanical Equipment

Electrofusion Welding Machine: Used for hot-melt connection of HDPE pipes to ensure pipe sealing.

Butt Welding Machine: Suitable for butt welding of large-diameter HDPE pipes.

Angle Grinder: Used for grinding pipe end faces to ensure a smooth weld surface.

Electric Welding Machine: Used for welding metal pipe fittings or supports.

Cutting Machine: Used for cutting pipes to ensure vertical cuts.

Level: Used for leveling pipes during installation.

II. General and Special Tools

Wrench, Screwdriver: Used for tightening pipe connections.

File: Used for smoothing burrs on pipes.

Wooden Hammer: Used for tapping and adjusting pipes during installation.

III. Measurement, Inspection, and Testing Equipment

Steel Tape Measure: Used for measuring pipe length.

Vernier Caliper: Used for precise measurement of pipe diameter.

Angle: Used for calibrating pipe angles.

Level: Used for leveling pipes during installation.

IV. Other Tools

Cable ties: Used for securing pipes, such as pre-installing siphon drainage pipe fittings.

Marker: Used for positioning marks before pipe installation.