HDPE is very popular among plastic manufacturers and pipe enthusiasts these days, and for good reason. It is a material of choice for pipes and other plastics because of its chemical resistance, acid, alkali and organic solvent resistance.

If you have heard the name HDPE in the corridors of your company and wondered what it is, or if you are a pipe manufacturer considering whether it is worth investing in, this article is for you. Read on to learn more.

Composition of HDPE

Basic monomer

Using high-purity ethylene (>99.9%) as the main polymerization monomer, polymer chains are formed through polymerization reactions

Comonomers

A small amount of α-olefin comonomers (such as 1-butene, 1-hexene, etc.) may be added during the production process to adjust the molecular chain branching structure and optimize the material toughness and processing performance

Properties of HDPE

The properties of HDPE are very attractive to plastic processors and engineers. Its excellent toughness allows it to withstand high stresses in a variety of applications, while its high hardness makes it durable. The following are some of the main properties of HDPE.

1.High strength and rigidity

HDPE has a relatively high density, but it still maintains good strength and rigidity, which makes it excel when it comes to carrying heavy loads.

2.Excellent chemical resistance

HDPE has excellent resistance to many chemicals, including most acids, bases, salts, and alcohols. However, it may be attacked by some organic solvents.

3.Excellent wear resistance

HDPE has a smooth and hard surface, so it has good wear resistance and is suitable for applications that require long-term resistance to wear.

4.Good impact resistance

Even in low temperature environments, HDPE can maintain good impact resistance and is not prone to brittle cracking.

4.Easy to process and shape

As a thermoplastic, HDPE can be processed through a variety of processes such as blow molding, injection molding, and extrusion, and is suitable for manufacturing products of various shapes and sizes.

Advantages of HDPE

To achieve the best requirements and highest efficiency, you need to evaluate some of the benefits you can gain from using a specific material. HDPE has many advantages. Let’s explore five of its main advantages:

1.High Strength and Durability

HDPE has high tensile strength and good impact resistance. It can maintain its toughness even under low temperature conditions and is not easy to break.

2.Lightweight

Compared with traditional materials such as metal, HDPE has a lower density and lighter weight, which helps to reduce the weight of the product and facilitates transportation and installation.

3.Good processing performance

HDPE is easy to form through various processes such as extrusion, injection molding, blow molding, etc., and is suitable for producing products with various complex shapes.

4.Environmentally friendly and recyclable

As a thermoplastic, HDPE can be recycled and reused many times, which helps reduce environmental pollution and resource waste.

5.Low moisture absorption

HDPE has a low ability to absorb moisture, which means it can resist the effects of humid environments and is suitable for outdoor use or underwater applications.

Common Applications

The properties and benefits of HDPE make it a preferred solution for many industrial applications. Here are five common applications:

1.Plastic bottles and containers

HDPE is commonly used to make bottles and containers for a variety of food, beverages and personal care products because it is non-toxic and has good chemical resistance.

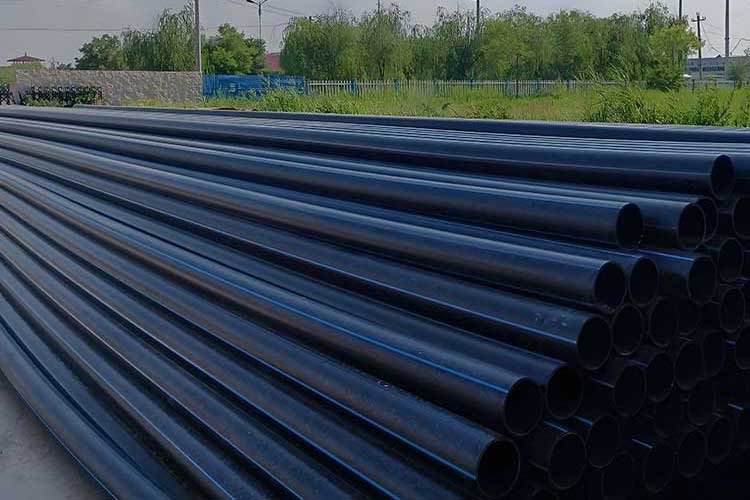

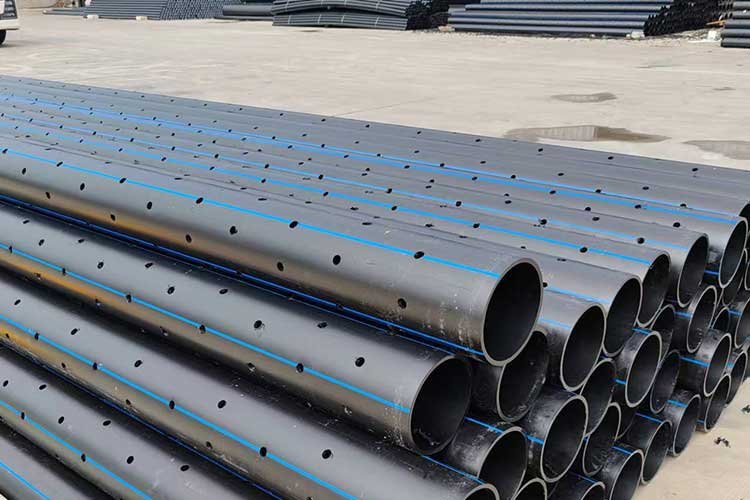

2.Pipe system

In construction and municipal engineering, HDPE pipes are widely used in water supply and drainage systems, gas transmission, sewers, and agricultural irrigation, etc., because they are corrosion-resistant, have smooth inner walls with low resistance, and are easy and reliable to connect.

3.Geomembrane

HDPE geomembrane is used in anti-seepage projects such as landfills, artificial lakes, reservoirs, etc., because of its excellent resistance to environmental stress cracking and good resistance to a variety of chemicals.

4.Industrial packaging

Such as pallets, barrels, boxes, etc., are suitable for transporting and storing chemicals or other industrial products because they can withstand heavy loads and provide good protection.

5.Cable sheath

Due to its excellent electrical insulation properties, HDPE is also used for the outer layer protection of wires and cables to prevent mechanical damage and external environmental influences.

Comparison with Other PE

| characteristic | ПНД | Comparison Notes |

|---|---|---|

| Molecular structure | Linear, less branched | LDPE contains a large number of long chain branches, while LLDPE is a short chain linear structure. |

| Crystallinity | 80%–90% | LDPE has a crystallinity of only 55%–65% |

| Main Application | Pipes, hollow containers, industrial sheets | LDPE is mainly used in the film field |

Висновок

That’s all we know about HDPE. This material offers a good balance between hardness, toughness, and wear resistance. In addition, it is easy to heat treat and is very simple to process. Its characteristics and comparison with other PEs help us make an informed decision based on specific needs.