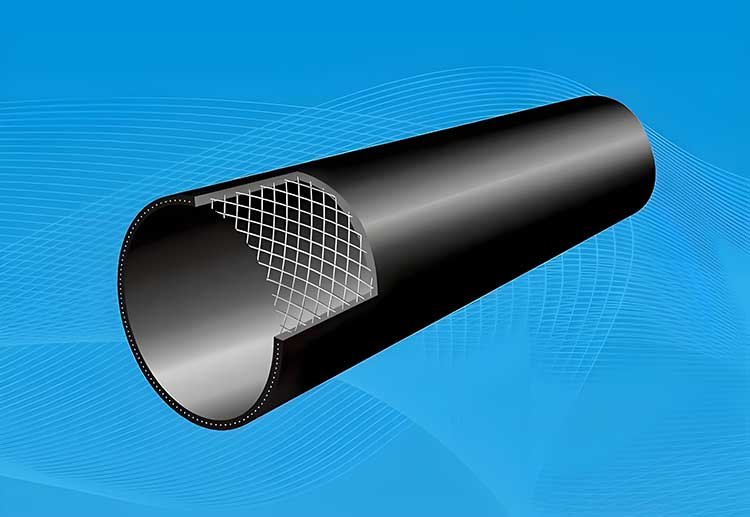

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire mesh composite pipe is a new type of pipe that combines a steel wire mesh skeleton with a high-density polyethylene (HDPE) matrix, offering satisfactory high pressure resistance and excellent flexibility. This article provides clear and comprehensive information on the characteristics, connections, performance, and applications of PE steel wire mesh composite pipe. You might consider using it for municipal water supply and drainage.

¿Qué son los tubos compuestos de malla metálica de acero PE?

PE steel wire mesh composite pipe is a composite pipe that combines the high strength of steel wire mesh with the corrosion resistance of polyethylene. This type of pipe has high pressure resistance, as well as excellent flexibility and corrosion resistance, enabling it to resist the erosion of a variety of chemical substances.

PE Steel Wire Mesh Composite Pipe Properties

High Pressure Resistance

Due to the reinforcing effect of the steel wire mesh skeleton, the steel wire mesh skeleton PE composite pipe has high pressure resistance.

Excellent flexibility

Combining the advantages of steel wire and plastic, it has excellent flexibility and is suitable for long-distance buried water supply and gas transmission pipeline systems.

Corrosion Resistance

Most PE steel wire mesh composite pipes are inherently corrosion-resistant, able to withstand humid environments and certain chemicals. For use in water supply systems, auxiliary surface treatment processes using virgin raw materials or environmentally friendly materials can be employed.

Good rigidity and impact resistance

The steel wire mesh reinforcement enhances the rigidity and impact resistance of the pipe, enabling it to withstand external impacts and vibrations. Therefore, if you are looking for suitable plastic pipes for complex terrain and long-distance laying, PE steel wire mesh composite pipe is an ideal choice.

PE Steel Wire Mesh Composite Pipe Connection

Electrofusión

Precise parameter control is crucial during the welding implementation phase: Taking DN160 PE steel wire mesh reinforced composite pipe fittings as an example, a 45V voltage must be applied continuously for 180 seconds. During welding, the condition of the observation hole must be closely monitored; a small amount of molten PE should seep out in the first 30 seconds, and voltage fluctuations must not exceed 5% of the set value. For pipes above DN300, a 0.5mm thermal expansion gap should be reserved during assembly to prevent welding backlash.

Conexión de enchufe de fusión en caliente

Compared to traditional mechanical connections, hot-melt socket welding has three major advantages: First, it has excellent sealing performance, with the molten interface forming a homogeneous connection layer that can withstand pressures of over 1.6 MPa; second, it has high construction efficiency, with the connection time for a single interface controlled within 3-5 minutes; and third, it has strong corrosion resistance, with no exposed metal parts, making it suitable for acidic and alkaline environments.

Preparation Process

The manufacturing process of PE steel wire mesh composite pipe includes raw material mixing, in-extruder melting and plasticizing, die forming, flanging, finishing and inspection, and other steps. During production, it is necessary to control the machine’s output pressure and heating temperature to ensure the quality of the pipe.

Applications of PE steel wire mesh composite pipes

Suministro municipal de agua y alcantarillado: Suitable for municipal water supply and drainage projects due to its good corrosion resistance, pressure resistance, and lightweight, easy installation.

Chemical and petroleum industries: It has good chemical corrosion resistance and is suitable for fluid transportation in chemical and petroleum fields.

Power and telecommunications: It can be used to protect pipe from external damage due to its insulation properties and stable mechanical properties.

Riego agrícola: It is resistant to aging, cold, and high temperatures, making it suitable for agricultural irrigation projects.

Preguntas frecuentes

How to install PE steel wire mesh composite pipe?

I. Pre-Installation Preparation

Material Inspection: Pipe surfaces should be smooth and free of bubbles and cracks; the wire mesh and PE layer should be tightly bonded; pipe fittings should match specifications; the copper wire windings of electrofusion fittings should be intact and undamaged.

Handling and Storage: Handle with care to avoid impact; for long-distance transportation, securely fix the pipes to prevent deformation. Storage should be on a flat, dry, and well-ventilated site, away from heat sources and sharp objects. Pipes should be stacked horizontally, with a stacking height not exceeding 2 meters, and the bottom layer supported by supports.

II. Installation Process

Measurement and Layout: Based on the design drawings and site benchmarks, use instruments such as a total station and level to mark the pipe axis, elevation, support and hanger positions, and inspection well positions. Layout deviation requirements: Axis position ≤ 10mm, elevation ≤ 5mm.

Pipe Connection

Electrofusion Connection (Common Method):

Pipe Cutting: Use a dedicated cutting machine to cut vertically, ensuring a clean, burr-free cut, and remove debris and oil from the end face.

Cleaning and Insertion: Wipe the outer surface of the pipe and the inner surface of the fitting with a clean cotton cloth. Insert the pipe into the electrofusion fitting to the marked depth, ensuring coaxiality and no misalignment.

Electrofusion Welding: Set the voltage and time according to the manufacturer’s welding curve. Connect the copper wire winding of the fitting to the output end of the welding machine. Do not move the pipe/fitting during welding. Allow to cool naturally for ≥30 minutes after completion.

Flange Connection (Auxiliary Method): Connect the flange to the pipe via electrofusion/thermal fusion (electrofusion flanges are installed according to electrofusion requirements; thermal fusion flanges require heating the pipe and flange socket before butt jointing and cooling to solidify).

Place rubber gaskets (compatible with the medium, such as EPDM gaskets for water supply and drainage) between the flanges. Align the bolt holes and tighten the bolts evenly to avoid uneven stress.

Pipe Laying

Trench Laying:

Trench Excavation: The trench bottom width should be “pipe diameter + 0.6~0.8 meters”. The trench bottom should be flat and free of sharp debris. Soft soil foundations need to be replaced with sand and gravel (compaction ≥90%) or reinforced.

Pipeline lowering: Use a crane/specialized equipment to lower the pipe, ensuring evenly distributed lifting points; lower it slowly into the trench, avoiding violent collisions with the trench walls and bottom.

Pipeline adjustment: After laying, adjust the axis and elevation. The axis deviation between adjacent pipes should be ≤5mm, and the elevation deviation ≤3mm.

Overhead laying: Support and hanger installation: Install corrosion-resistant supports and hangers according to the design spacing (using rubber pads at pipe contact points). The spacing between supports and hangers for horizontal pipes should be 2-3 meters (this can be reduced for larger diameter pipes).

How to check the connection quality of PE steel wire mesh composite pipe?

I. Appearance and Dimensional Inspection

Appearance Inspection: Welded areas should be smooth and flat, free from defects such as bubbles, cracks, and delamination.

Dimensional Inspection: Measure pipe diameter and ovality using an optical projector, and perform a grid scan of the entire pipe wall thickness using ultrasonic waves.

II. Mechanical Property Testing

Tensile Test: Prepare dumbbell-shaped specimens according to standards for tensile testing, and record the tensile force at failure.

Peel Strength Test: Determine the peel strength between the steel wire and polyethylene using a clamp method to ensure a strong bond.

III. Sealing Test

Hydrostatic Pressure Test: Apply pressure in stages under constant temperature conditions, record pipe deformation and pressure holding performance, and ensure no leakage.