I. Core Method: Solvent Bonding (Essential, applicable to most PVC-U drainage pipes)

This is the most common and reliable bonding method for PVC drainage pipes. The operation steps are clear, and the key is “cleaning, drying, applying glue, butt joint, and curing,” each step is indispensable.

Required Materials and Tools

Special Consumables: PVC-U drainage pipe-specific glue (must match the pipe specifications, such as ordinary pipe/thickened pipe, to avoid using the wrong glue), PVC pipe cleaner (optional, enhances bonding effect);

Tools: Measuring tape, pipe cutter (or fine-toothed saw), chamfering tool (or sandpaper), cotton cloth/dry cloth, gloves, brush (included with glue or special brush, brush width matched to pipe diameter).

Detailed Operating Procedures

Pipe Cutting and Chamfering: Cut the pipe to the required length using a pipe cutter (recommended for a clean cut) or a fine-toothed saw. After cutting, use a chamfering tool or sandpaper to smooth the inner and outer edges of the pipe ends (remove burrs, chamfer at a 45° angle) to avoid sharp edges scratching the inner wall of the fittings and affecting the seal.

Crucial: The cut must be perpendicular to the pipe axis; it cannot be skewed, otherwise leakage is likely after connection.

Cleaning and Drying: Use a cotton cloth dampened with PVC cleaner (or water) to wipe the outer wall of the pipe insertion end and the inner wall of the fitting socket to remove oil, dust, moisture, and oxide layer (oxide layer can cause weak adhesion).

After wiping, the pipe must be completely dry (no moisture, no residue). Moisture will impair the dissolving effect of the adhesive, leading to bonding failure.

** Trial Insertion and Positioning: Before applying adhesive, insert the pipe into the fitting socket to test the insertion depth (generally, the insertion depth is 2/3 of the fitting socket length, or align with the scale lines on the fitting). Confirm that it can be inserted smoothly without looseness to avoid misalignment after applying adhesive.

Even Adhesive Application: Wearing gloves, use a brush to apply a sufficient amount of PVC-specific adhesive. First, apply it evenly to the inner wall of the fitting socket (covering the entire circumference, especially the bottom of the socket). Then, apply it to the outer wall of the pipe insertion end (again, covering the entire circumference; the coating thickness should be moderate, enough to cover the surface without dripping).

Note: Do not apply too little adhesive (the bonding surface will not be fully saturated, resulting in poor adhesion), nor too much adhesive (excess adhesive will clog the pipe or create burrs after curing, affecting drainage). Quick Connection and Fixing: Immediately after applying the adhesive, insert the pipe into the fitting socket in one go (aligning with the depth used for the initial insertion). During insertion, gently rotate the pipe 1/4 turn (to ensure even adhesive distribution and avoid areas without adhesive), but do not pull or rotate it after insertion.

After insertion, fix the pipe and fitting together by hand or with clamps for 30-60 seconds (initial curing, to prevent detachment). Do not apply excessive pressure during fixing to prevent pipe deformation.

Curing and Maintenance:

Initial Curing: Within 30 minutes of connection, avoid moving the pipe or applying external force, as the adhesive is not fully cured at this time, and stress can easily cause the joint to crack.

Complete Curing: At room temperature (20-25℃), small-diameter pipes (≤110mm) require 2-4 hours of curing, and large-diameter pipes (≥160mm) require 8-24 hours of curing. Do not pressure test with water during the curing period (the adhesive will dissolve in water before curing, rendering it ineffective). 3. Key Precautions

Specific Adhesive Required: Do not use silicone sealant, AB glue, or other similar adhesives as substitutes for PVC-specific adhesive. The former cannot dissolve PVC, leading to easy detachment and leakage after bonding.

Environmental Requirements: The operating temperature must be between 5 and 40°C. Low temperatures (<5°C) will prolong curing time, while high temperatures (>40°C) will cause the adhesive to evaporate rapidly, resulting in insufficient bonding time after application.

Socket and Pipe Matching: PVC-U pipes and fittings of the same specification and material must be used (e.g., DN50 pipe with DN50 fittings). Gaps that are too large or too small will affect the bonding effect (the gap is generally 0.1~0.2mm of the pipe’s outer diameter).

Repair Prohibited: If the joint is misaligned after applying adhesive, do not forcibly pry it open. The pipe must be cut and the process repeated. Adhesive-covered joints cannot be repaired a second time. II. Auxiliary Reinforcement Methods (Only used as a supplement to solvent bonding, not for standalone use)

These methods enhance the sealing and tensile strength of the joint, especially suitable for large-diameter pipes (≥200mm), outdoor exposed pipes, or vibrating environments. They must be used in conjunction with solvent bonding.

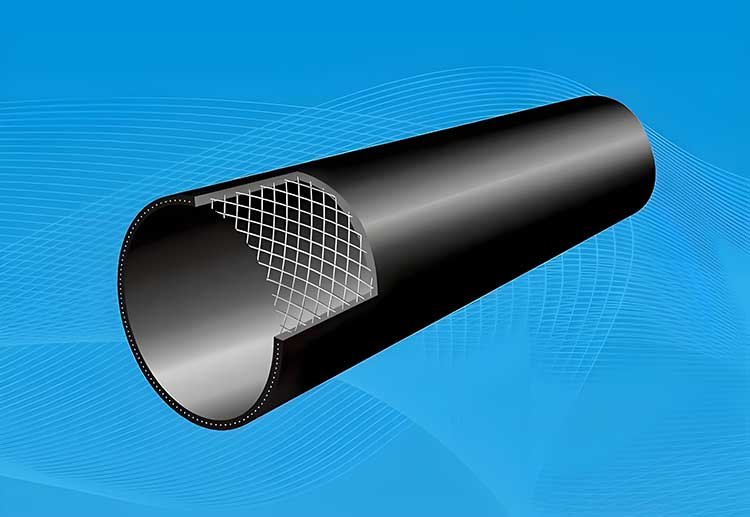

Bonding + Rubber Ring Auxiliary Sealing

Operation: First, complete the butt joint and curing of the pipe and fitting using solvent bonding. Then, place a dedicated PVC pipe sealing rubber ring (matching the pipe diameter) on the outside of the joint, or pre-embed a rubber ring inside the fitting socket (some dedicated fittings come with one). Then apply adhesive and join the pipe.

Advantages: Double sealing, vibration resistance, resistance to minor deformation, reduces the risk of leakage due to pipe settlement. Commonly used for outdoor drainage pipes or long-distance pipe laying.

Adhesive Bonding + Flange Fixing (Suitable for large-diameter pipes or scenarios requiring disassembly)

Operation: First, use solvent to bond and fix the PVC flange (dedicated) to the pipe. When connecting, place a rubber gasket between the two flanges, and then tighten the flanges with bolts.

Advantages: The adhesive ensures a seal, the flange enhances tensile strength, and it allows for subsequent disassembly and maintenance (ordinary solvent bonding is one-time use and cannot be disassembled). Suitable for large-diameter pipes above DN315mm, or scenarios requiring maintenance such as sewage treatment plants and industrial pipelines.

Adhesive Bonding + Tape Wrapping (Emergency or Temporary Reinforcement)

Operation: After the solvent bonding has cured, wrap the entire circumference of the joint with PVC-specific waterproof tape (or self-adhesive rubber tape) 3-5 times. Pull the tape taut while wrapping to ensure it adheres to the pipe surface.

Suitable Scenarios: Temporary repair of minor leaks at joints (not a long-term solution), or protection of outdoor pipe joints from UV aging (to prevent long-term exposure and cracking of the adhesive).