The primary function of corrugated pipes is to transport fluids, gases, and solid particles across various industrial sectors. Due to their flexibility, adjustability, and corrosion resistance, they are widely used in industries such as petrochemicals, power generation, automotive manufacturing, aerospace, and construction.

What is a corrugated pipe?

corrugated pipe is a flexible pipe with a wavy shape, made of high-quality metal or plastic. Compared with traditional rigid pipes, corrugated pipes have many unique advantages and are therefore widely used in various industrial and civil fields.

Types of corrugated pipes

Stainless steel corrugated pipe

This high-quality stainless steel pipe offers excellent corrosion resistance and resistance to high temperatures and pressures. It is suitable for conveying various liquid or gaseous media, such as oil, chemicals, and natural gas, and is particularly suited for high-temperature and high-pressure environments.

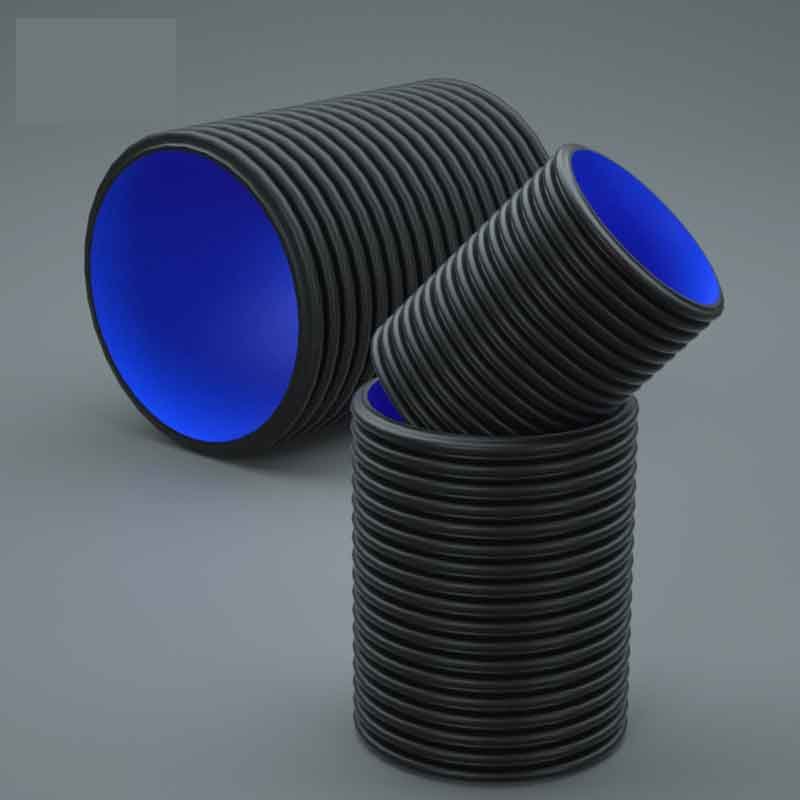

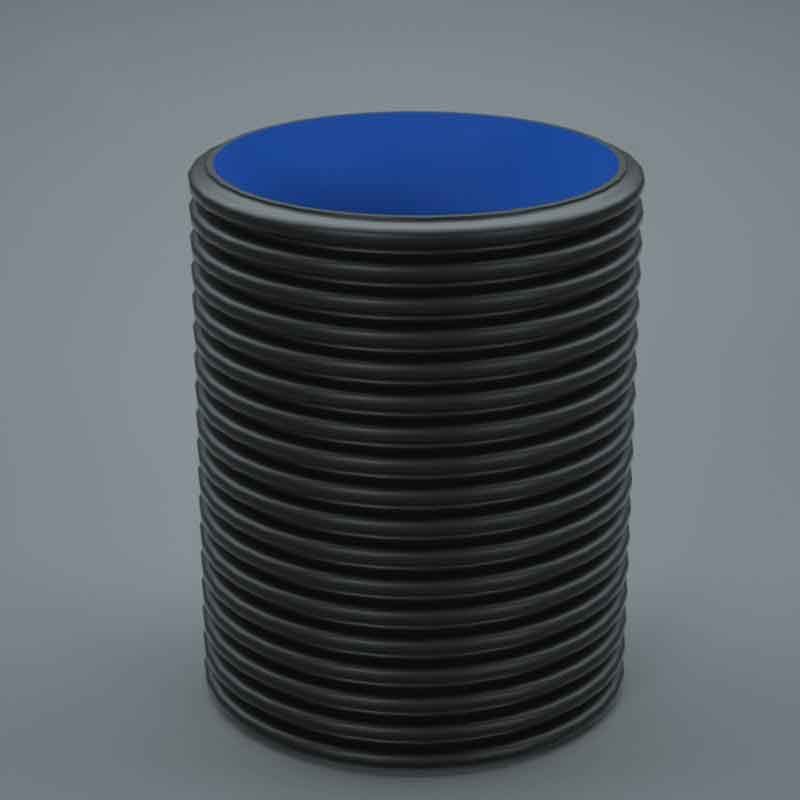

Tube ondulé en PEHD

Made from high-density polyethylene, it offers excellent acid, alkali, and corrosion resistance. It is widely used in water supply and drainage, ventilation ducts, and industrial waste gas discharge.

Corrugated copper tubing

Made from pure copper, it offers excellent thermal and electrical conductivity. It’s widely used in condensers, heaters, air conditioning systems, and electronic equipment to transfer heat or electrical signals.

Feature of corrugated pipes

Excellent Flexibility and Plasticity

Corrugated pipes offer excellent flexibility, adapting to various complex piping layouts and bending requirements. This reduces the need for connecting fittings, lowering installation difficulty and costs.

Excellent Corrosion Resistance

Bells are often made of highly corrosion-resistant metal materials such as stainless steel and copper. They are resistant to chemical corrosion, high temperatures, and high pressures, ensuring a long service life.

Excellent Sealing Performance

Bellows, through welding or clamp connections, ensure a tight seal in piping systems, effectively preventing leaks and ensuring safe and stable operation.

Strong vibration resistance and absorption capacity

The corrugated pipe’s internal wavy structure provides a certain degree of cushioning and absorption capacity, effectively reducing vibration and noise in the system, improving the stability and comfort of the piping system.

Application of corrugated pipes

Industrial Piping Systems

Corrugated pipes are widely used in piping systems in industries such as chemical, petroleum, power, and shipbuilding, transporting various liquids and gases.

Automotive Manufacturing

Bells are commonly used in automotive exhaust systems, braking systems, and other applications. They can withstand vehicle vibration and high temperatures, improving vehicle performance and reliability.

Ingénierie de la construction

Corrugated pipes can be used in building drainage systems, natural gas pipelines, and other applications, adapting to changes in building structure and pipeline layout requirements.

Conclusion

Driven by technological innovation and market demand, the development trend of bellows will continue to move toward high performance, energy conservation, environmental protection, and intelligence. This will provide more reliable and efficient solutions for industrial production and environmental protection.