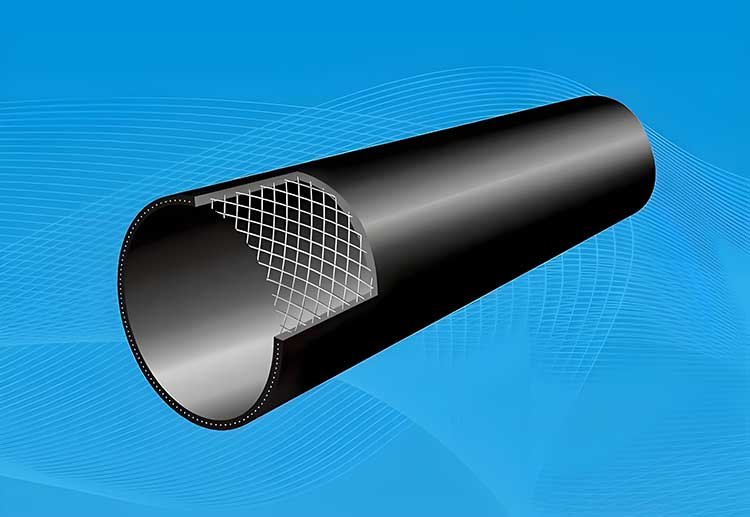

12 Tubo de PEAD

Envie sua consulta hoje mesmo

12 Fabricante de tubos de PEAD

12 O tubo de PEAD é um tubo de plástico de alto desempenho que se tornou um substituto dos tradicionais tubos de metal e de concreto devido às suas excelentes propriedades físicas e químicas.

12 Características do tubo PEAD

Propriedades mecânicas

Alta resistência à tração, resistência ao impacto (teste de impacto de martelo de queda ≤10% dano a 23°C), rigidez do anel ≥8kN/m² (para tubos de drenagem), adaptável ao assentamento da fundação;

Propriedades químicas

Resistente a ácidos (pH 2~13), resistente a álcalis e resistente a soluções salinas, ele não reage com a maioria dos produtos químicos e é superior aos tubos de ferro fundido e aço;

Desempenho do fluido

A parede interna é lisa (rugosidade k=0,009 mm), o atrito hidráulico é pequeno, a taxa de fluxo é 30% maior do que a dos tubos de concreto com o mesmo diâmetro de tubo, e não é fácil escalonar;

12 Campos de aplicação de tubos de PEAD

12 O tubo HDPE é amplamente utilizado em muitos campos devido ao seu excelente desempenho:

Engenharia municipal:

Rede urbana de abastecimento de água e drenagem, instalação integrada de corredores de tubulação;

Projetos de conservação de água:

Irrigação de terras agrícolas, transferência de água do reservatório, gerenciamento de rios;

Área industrial:

Transporte de materiais em fábricas de produtos químicos, farmacêuticos e alimentícios;

Projetos de proteção ambiental:

Coleta de lixiviados de aterros sanitários, sistemas de tubulação para estações de tratamento de esgoto.

Pontos de conexão e instalação

- Na soldagem de topo por fusão a quente: a temperatura de aquecimento (geralmente de 190 a 230°C) e o tempo de aquecimento (ajustado de acordo com a espessura da parede do tubo, o tempo de aquecimento para um tubo de 12 polegadas é de cerca de 5 a 8 minutos) devem ser rigorosamente controlados. O tubo não deve ser movido durante o processo de resfriamento para evitar rachaduras na interface.

- Ao fazer a conexão de fusão elétrica: uma máquina de fusão elétrica especial deve ser usada e operada de acordo com os parâmetros especificados (tensão, tempo). Após a conclusão da conexão, ela deve ser resfriada naturalmente por ≥30 minutos. Nenhuma força externa é permitida durante o período de resfriamento.

- Ao cruzar áreas especiais, como estradas e rios, é necessário adicionar um revestimento protetor. O diâmetro interno do revestimento deve ser de 100 a 200 mm maior do que o diâmetro externo do tubo PEAD, e ambas as extremidades devem ser vedadas para evitar a entrada de lama e areia.

- Ao transportar meios que contenham partículas sólidas, o tamanho da partícula deve ser controlado para ≤5 mm e a concentração deve ser ≤10% para evitar erosão a longo prazo e desgaste da tubulação.

- Depois que a tubulação for instalada e passar no teste de pressão da água, ela deverá ser preenchida a tempo. O material de preenchimento deve ser solo fino ou areia média-grossa com tamanho de partícula ≤5 mm. É estritamente proibido usar objetos duros, como pedras e tijolos.

Artigos relacionados

O que é soldagem por eletrofusão de PE?

Os métodos mais comuns de conexão de tubos PE na instalação de tubulações incluem: conexão por fusão térmica, eletrofusão...

O que é o tubo composto de malha de arame de aço PE?

Você está procurando plásticos adequados para o abastecimento e a drenagem de água municipal? Fio de aço PE...

Guia abrangente da tecnologia de tubos PE sem vala

Com a aceleração da urbanização global, a construção municipal exige o assentamento e a substituição de um...

Por que usar tubos de PEAD em sistemas de drenagem por sifão?

Quando chove, você pode ouvir ocasionalmente um som borbulhante assustador vindo dos canos de esgoto,...

Designação das especificações dos tubos – Guia completo

As especificações dos tubos são normalmente indicadas utilizando vários métodos, tais como DN, polegadas, D, Φ, De, etc.

Como calcular a espessura da parede de um tubo PE

Os tubos PE são amplamente utilizados no abastecimento e drenagem de água urbana, gás, telecomunicações e energia...