With the acceleration of global urbanization, municipal construction requires the laying and replacement of a large number of underground pipelines. Especially in today’s rapidly developing China, urban residents have a strong environmental awareness and demand that projects do not involve digging up roads, damaging grasslands and surrounding landscapes, etc.

During construction, when water pipes become damaged or worn over time, pipeline specialists have to excavate and repair them, paying close attention to every section of the pipe. Repairing pipes in this way is not only costly and labor-intensive, but also destructive to the surrounding environment. Now, thanks to modern trenchless pipeline technology, it is possible to restore old pipelines to full serviceability using cost-effective and sustainable methods.

What is trenchless technology?

Trenchless technology refers to a series of underground pipe installation methods. These are new construction technologies for laying, replacing, and repairing various underground pipelines without excavating trenches on the surface. They involve using methods such as directional drilling and guidance to achieve this, with only minimal excavation on the surface (generally referring to small-area excavation at the inlet and outlet).

Compared to traditional trenching methods, trenchless technology offers advantages such as minimal disruption to traffic, no environmental damage, shorter construction time, and significant social benefits. It can minimize interference with road traffic, lawns and gardens, commercial operations, and other activities.

Trenchless pipe laying technology has a wide range of applications. It can be used to lay pipelines across busy highways, railways, buildings, rivers, and in urban areas. It is widely used in the construction of new pipelines and the repair of old pipelines in the fields of water supply, drainage, electricity, communications, and gas. It can also be used for the protection of cultural relics and ancient buildings.

Application of trenchless technology in pe pipes

PE pipe is the most commonly used pipe type in trenchless construction and has been widely used in the following four common trenchless construction methods, and has also been successfully applied in China.

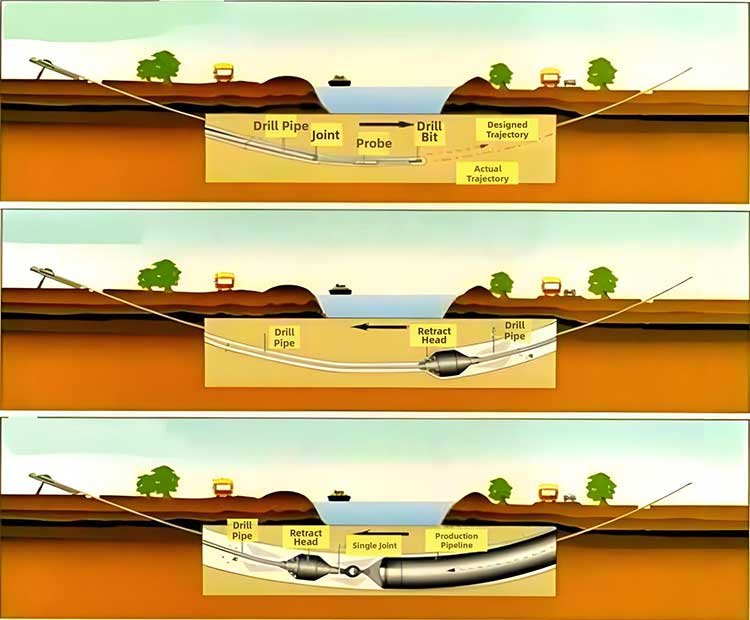

Horizontal directional drilling pipe laying

Directional drilling is a drilling method that enables rapid installation of underground pipelines without the need for excavating a working well. Its main characteristic is that, according to a pre-designed pipeline route, a drill rod equipped with a wedge-shaped drill bit is driven into the ground, then follows a predetermined direction around underground obstacles until the destination is reached. Then, the drill bit is removed and replaced with a specially sized and type of return reamer, which enlarges the borehole to the required diameter while simultaneously pulling back the drill rod. The pipeline to be laid is simultaneously pulled back to the borehole entrance to ensure that the newly laid pipeline is not damaged due to insufficient space or friction from drill cuttings.

It is now widely used in telecommunications pipelines, power pipelines, natural gas pipelines, and water supply pipelines.

Advantages of directional drilling:

(1) No need to excavate a working well; suitable for laying pipelines of various materials with diameters ranging from 100mm to 1000mm;

(2) A drilling system with maximum torque and a unique design can handle most geological conditions;

(3) A specially designed wedge-shaped drill bit allows for easy adjustment of the drilling direction to avoid obstacles;

(4) The guiding and positioning system can measure depths up to 30.5m, ensuring accurate construction routes;

(5) Rapid construction; a single drilling operation can reach a distance of up to 600m;

(6) Suitable for laying trenchless pipelines of various materials, especially HDPE solid-wall pipes.

Pipe cracking method for replacing old pipes

This method involves breaking up the old pipe and squeezing it into the surrounding soil. Then, a new pipe is pulled into the original pipe’s location. Typically, a pneumatic (high-pressure air) or static (hydraulic) pipe-breaking system is used to break the old pipe. A PE pipe is connected after the broken end. When the old pipe is completely broken, the new HDPE pipe is also laid, thus replacing the old pipe.

The advantage of this method is that the diameter of the new pipe can be equal to or even larger than the replaced old pipe. The disadvantage is that because the new pipe is inserted into the surrounding broken old pipe, it is inevitably damaged. Therefore, the pipe material must have exceptionally good damage resistance, wear resistance, and crack resistance.

Repairing old pipes using intubation method

This technology involves inserting a plastic liner into an old pipe. Depending on whether the liner’s outer diameter fits snugly against the inner wall of the old pipe, it can be divided into two categories: “slip-lining” and “fitting liner.”

The slip-lining method involves inserting a new polyethylene pipe with an outer diameter slightly smaller than the old pipe’s inner diameter into the old pipe to be repaired. The gap between the new and old pipes can be sealed by injecting mortar.

The fitting liner method involves inserting a new plastic liner with an outer diameter equal to the old pipe’s inner diameter into the old pipe through methods such as “diameter reduction” or “inward folding.” Then, the liner is allowed to naturally recover its shape or is restored to its original shape through pressurization and heating, achieving a snug fit against the inner wall of the old pipe. The fitting liner can share the internal pressure with the old pipe.

This method is only suitable for repairing large-diameter pipes, and the pipe’s flow cross-sectional area loss is relatively large.

Pneumatic spear pipe laying

Trenchless pipe laying is performed using a spear-shaped drill bit via impact. The drive mechanism is mostly pneumatic (but hydraulic can also be used), commonly referred to as the pneumatic spear pipe laying method. The pneumatic spear is supported and propelled forward by the friction between the hammer and the soil, creating a hole through compression under impact. The pipeline to be laid is connected to the pneumatic hammer and is laid as the hammer advances through the soil. Alternatively, the PE pipe can be pulled back into the hole after the pneumatic spear has completed drilling.

This method is simple, efficient, and low-cost. Pipe laying lengths are generally within 40m, and pipe diameters range from 40 to 200mm. It is suitable for various soil types. The latest tools include a reciprocating chisel head, allowing use in gravelly soils.

Key advantages of trenchless technology

Save time and interruption

Traditional excavation processes take longer than other pipe installation or repair methods. Digging trenches under roads means work must be completed at night to minimize traffic disruption. Trenchless installation and repair allows for faster repair of damaged pipes, even during heavy traffic periods, and permits tunneling under roads.

Cost-saving: Trenchless technology is often the most cost-effective option because it eliminates the need for large technicians, traffic managers, excavators, gardeners, etc. Trenchless methods also minimize equipment and tooling requirements and reduce your labor costs. A less obtrusive and environmentally friendly alternative: Trenchless technology involves very little excavation, resulting in minimal damage to the surrounding landscape. Trenchless installations also require no structural modifications, such as demolishing walls or resurfacing, making it as easy as possible to install pipe infrastructure.

Making HDPE pipes more durable

HDPE borular offer greater flexibility, damage resistance, and leak-proofness than standard PVC, steel, or concrete pipes. Using HDPE pipes with trenchless technology provides you with unparalleled pipe durability.

Sonuç

Trenchless PE pipe technology boasts advantages such as minimal construction disturbance, low environmental impact, short construction period, and high cost-effectiveness. Employing trenchless techniques such as directional drilling, pipe bursting to replace old pipes, and pipe insertion to repair old pipes for laying or repairing polyethylene (PE) pipelines not only effectively avoids the disruption to traffic, commerce, and residential life caused by traditional “open-cut” construction, but also significantly improves the overall sealing and durability of the pipeline network system.