3 Hdpe Boru

Sorgunuzu Bugün Gönderin

3 Hdpe Boru Üreticisi

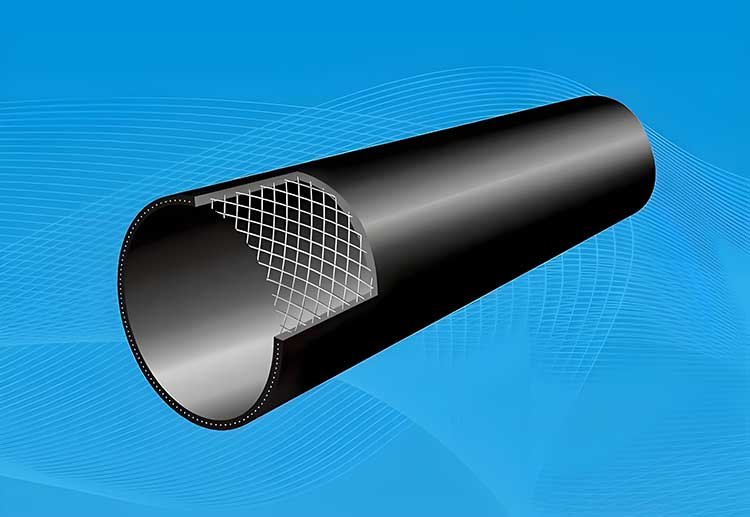

3 HDPE boru yüksek performanslı bir plasti̇k boru mükemmel fiziksel ve kimyasal özellikleri nedeniyle geleneksel metal boruların ve beton boruların yerini almıştır.

3 HDPE Boru Özellikleri

Fiziksel Özellikler

Esneklik: Bükülme yarıçapı boru çapının ≥25 katı olabilir, temel oturmasına veya arazi dalgalanmalarına uyum sağlayabilir ve bağlantı sayısını azaltabilir.

Hafiftir: Yoğunluk yaklaşık 0,94-0,96 g/cm³'tür ve ağırlık, düşük nakliye ve kurulum maliyetleri ile çelik borunun yalnızca 1/8'i kadardır.

Kimyasal Özellikler

Korozyon direnci: Asit, alkali, tuz çözeltisi (pH4-10) ve toprak korozyonuna dayanıklıdır, ek korozyon önleyici işlem gerekmez ve hizmet ömrü 50 yıldan fazladır.

Düşük geçirgenlik: Moleküler yapı yoğundur ve su buharı geçirgenliği 0,01 g/(m・d)'den azdır, bu da ortamın sızmasını veya harici kirleticilerin sızmasını önler.

Mekanik Özellikler

Yüksek mukavemet: PE100 sınıfı gerilme mukavemeti ≥26MPa, iç basınca karşı güçlü direnç (SDR11 boru basınç direnci 1.0MPa gibi), mükemmel dış basınç darbe direnci (-40 ℃ damla çekiç darbe geçiş oranı ≥90%).

Termal Özellikler

Sıcaklık aralığı: Uzun süreli kullanım için -40 ℃ ila +60 ℃, kısa süreli kullanım için +70 ℃, ılıman ve soğuk iklimler için uygundur.

Sıcak eriyik: Arayüz, sıcak eriyik alın kaynağı ve elektrikli füzyon bağlantısı yoluyla entegre edilebilir. Mukavemet boru gövdesinden daha yüksektir ve sızdırmazlık güvenilirdir.

3 Hdpe Boru Uygulama Alanları

3 HDPE boru, mükemmel performansı nedeniyle birçok alanda yaygın olarak kullanılmaktadır:

Su şebekesi:

Kullanım suyunun taşınması için dökme demir boruların değiştirilmesi

Kimya endüstrisi:

Asit ve alkali çözeltileri, endüstriyel atık suların taşınması; Gıda endüstrisi: saf su, içecek hammaddelerinin taşınması, hijyen gereksinimlerinin karşılanması.

Kablo koruma kılıfı:

Yeraltına döşendiğinde güç ve iletişim kablolarını korur, toprak stresine ve böcek kemirmesine karşı dayanıklıdır.

İnşaat ve Kurulum Özellikleri

- Sıcak eriyik bağlantısı: düz boru bağlantısı için uygundur, özel sıcak eriyik makinesi gereklidir, ısıtma sıcaklığı 210 ± 10 ℃, soğutma süresi ≥ 30 dakikadır ve arayüz mukavemeti boru gövdesinin 90%'sinden daha fazlasına ulaşır

- Elektrikli füzyon bağlantısı: boru bağlantı parçaları (tees ve dirsekler gibi) için uygundur, önceden gömülü direnç teli elektrikli füzyon makinesi tarafından ısıtılır ve kaynaştırılır ve voltaj (220V gibi) ve ısıtma süresi (yaklaşık 90-120 saniye) kesinlikle kontrol edilmelidir.

- Flanş bağlantısı: metal borulara veya ekipmana bağlanırken kullanılır, HDPE flanş kökü ve kauçuk sızdırmazlık halkası gereklidir ve sızıntıyı önlemek için cıvata torku eşittir.

- İnşaat önlemleri: Yeraltına gömüldüğünde, kaplama derinliği ≥0,7 m (soğuk bölgelerde donmayı önlemek için ≥1,2 m) olmalı ve keskin taşlarla temastan kaçınılmalıdır; sıcak eriyik bağlantıları için, kirliliklerin mukavemeti etkilemesini önlemek için arayüzün temiz olduğundan emin olun.

İlgili Makaleler

PE Elektrofüzyon Kaynağı Nedir?

Boru hattı kurulumunda en yaygın PE boru bağlantı yöntemleri şunlardır: ısı füzyon bağlantısı, elektrofüzyon...

PE Çelik Hasır Kompozit Boru Nedir?

Belediye su temini ve drenajı için uygun plastikler mi arıyorsunuz? PE çelik tel...

Kazısız PE Boru Teknolojisi için Kapsamlı Kılavuz

Küresel kentleşmenin hızlanmasıyla birlikte, belediye inşaatları, bir dizi inşaat malzemesinin döşenmesini ve değiştirilmesini...

Sifon drenaj sistemlerinde neden HDPE borular kullanılır?

Yağmur yağdığında, ara sıra tahliye borularından gelen korkunç bir şırıltı sesi duyabilirsiniz...

Boru Spesifikasyonu Tanımı – Kapsamlı Kılavuz

Boru özellikleri genellikle DN, inç, D, Φ, De gibi çeşitli yöntemler kullanılarak belirtilir.

PE boru duvar kalınlığı nasıl hesaplanır?

PE borular, kentsel su temini ve drenaj, gaz, telekomünikasyon ve enerji alanlarında yaygın olarak kullanılmaktadır...