12 Hdpe Boru

Sorgunuzu Bugün Gönderin

12 Hdpe Boru Üreticisi

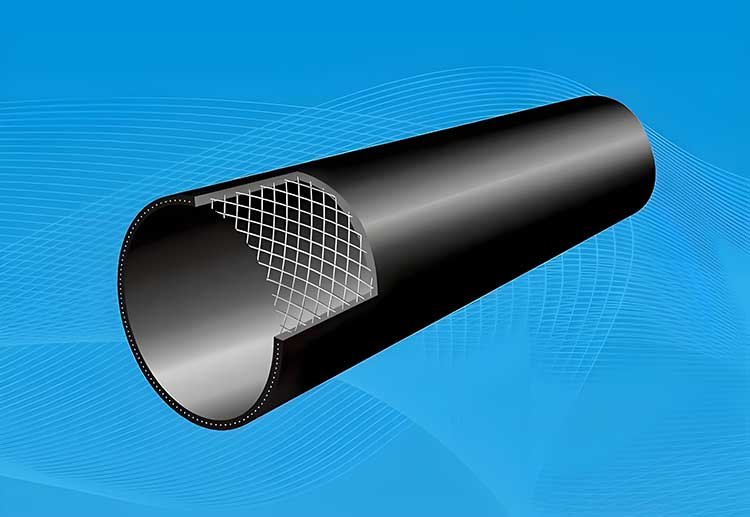

12 HDPE boru, mükemmel fiziksel ve kimyasal özellikleri nedeniyle geleneksel metal boruların ve beton boruların yerini alan yüksek performanslı bir plastik borudur.

12 HDPE Boru Özellikleri

Mekanik Özellikler

Yüksek çekme mukavemeti, darbe direnci (düşme çekiç darbe testi ≤10%, 23°C'de hasar), halka sertliği ≥8kN/m² (drenaj boruları için), temel oturmasına uyum sağlar;

Kimyasal Özellikler

Aside dayanıklı (pH 2~13), alkaliye dayanıklı ve tuz çözeltisine dayanıklıdır, çoğu kimyasal maddeyle reaksiyona girmez ve dökme demir ve çelik borulardan üstündür;

Akışkan Performansı

İç duvar pürüzsüzdür (pürüzlülük k=0,009 mm), hidrolik sürtünme azdır, akış hızı aynı boru çapındaki beton borulardan 30% daha yüksektir ve kireçlenmeye meyilli değildir.;

12 Hdpe Boru Uygulama Alanları

12 HDPE boru, mükemmel performansı nedeniyle birçok alanda yaygın olarak kullanılmaktadır:

Belediye mühendisliği:

Kentsel su temini ve drenaj ağı, entegre boru hattı koridoru döşeme;

Su koruma projeleri:

Tarım arazilerinin sulanması, rezervuar suyunun transferi, nehir yönetimi;

Endüstriyel alan:

Kimya, ilaç ve gıda fabrikalarında malzeme nakliyesi;

Çevre koruma projeleri:

Çöp depolama alanlarından sızıntı suyu toplama, atık su arıtma tesisleri için boru sistemleri.

Bağlantı ve Kurulum Noktaları

- Sıcak eriyik alın kaynağı yaparken: ısıtma sıcaklığı (genellikle 190-230℃) ve ısıtma süresi (borunun duvar kalınlığına göre ayarlanır, 12 inçlik bir borunun ısıtma süresi yaklaşık 5-8 dakikadır) sıkı bir şekilde kontrol edilmelidir. Arayüzün çatlamasını önlemek için boru soğuma işlemi sırasında hareket ettirilmemelidir.

- Elektrikli füzyon bağlantısı yaparken: özel bir elektrikli füzyon makinesi kullanılmalı ve belirtilen parametrelere (voltaj, süre) göre çalıştırılmalıdır. Bağlantı tamamlandıktan sonra, ≥30 dakika boyunca doğal olarak soğutulmalıdır. Soğutma süresi boyunca dış kuvvet uygulanmamalıdır.

- Yollar ve nehirler gibi özel alanları geçerken, koruyucu bir kılıf eklenmelidir. Kılıfın iç çapı, HDPE borunun dış çapından 100-200 mm daha büyük olmalı ve her iki ucu da çamur ve kumun sızmasını önlemek için sızdırmaz hale getirilmelidir.

- Katı parçacıklar içeren sıvıları taşırken, uzun süreli aşınma ve boru yıpranmasını önlemek için parçacık boyutu ≤5 mm ve konsantrasyon ≤10% olarak kontrol edilmelidir.

- Boru hattı kurulduktan ve su basıncı testinden geçtikten sonra, zamanında geri doldurulmalıdır. Geri doldurma malzemesi, ≤5 mm parçacık boyutuna sahip ince toprak veya orta-kaba kum olmalıdır. Taş ve tuğla gibi sert nesnelerin kullanılması kesinlikle yasaktır.

İlgili Makaleler

PE Elektrofüzyon Kaynağı Nedir?

Boru hattı kurulumunda en yaygın PE boru bağlantı yöntemleri şunlardır: ısı füzyon bağlantısı, elektrofüzyon...

PE Çelik Hasır Kompozit Boru Nedir?

Belediye su temini ve drenajı için uygun plastikler mi arıyorsunuz? PE çelik tel...

Kazısız PE Boru Teknolojisi için Kapsamlı Kılavuz

Küresel kentleşmenin hızlanmasıyla birlikte, belediye inşaatları, bir dizi inşaat malzemesinin döşenmesini ve değiştirilmesini...

Sifon drenaj sistemlerinde neden HDPE borular kullanılır?

Yağmur yağdığında, ara sıra tahliye borularından gelen korkunç bir şırıltı sesi duyabilirsiniz...

Boru Spesifikasyonu Tanımı – Kapsamlı Kılavuz

Boru özellikleri genellikle DN, inç, D, Φ, De gibi çeşitli yöntemler kullanılarak belirtilir.

PE boru duvar kalınlığı nasıl hesaplanır?

PE borular, kentsel su temini ve drenaj, gaz, telekomünikasyon ve enerji alanlarında yaygın olarak kullanılmaktadır...