Güçlü, sağlam bir plastik arıyorsanız, kesinlikle PP'yi denemelisiniz. Bu plastik, düşük yoğunluğu ve yüksek ısı direnci ile ünlüdür ve birçok endüstride yaygın olarak kullanılmaktadır. Bu makalede, avantajlarını anlamanıza yardımcı olmak için kimyasal bileşimini, özelliklerini ve pratik uygulamalarını inceleyeceğiz.

PP'nin Kimyasal Bileşimi

PP'nin moleküler formülü (C₃H₆)ₙ tekrarlayan birimidir, burada n polimerizasyon derecesini temsil eder. Basitleştirilmiş yapısal formülü [-CH₂-CH(CH₃)-]ₙ şeklinde ifade edilebilir; ana zincir karbon atomlarından oluşur ve ikinci karbon atomuna bir metil grubu (-CH₃) asılı olarak bağlanır. Bu doğrusal yapı malzemeye hafiflik (yoğunluk 0.89-0.92 g/cm³) ve ısı direnci (erime noktası 164-176°C) kazandırır.

PP'nin temel özellikleri

Hafif: PP hafif bir malzemedir, bu da taşımayı ve işlemeyi kolaylaştırır.

Kimyasal Direnç: Asitler, alkaliler ve solventler dahil olmak üzere birçok kimyasala karşı mükemmel korozyon direnci gösterir.

Isı Direnci: Yüksek ısı deformasyon sıcaklığına ve termal stabiliteye sahiptir, yüksek sıcaklıklarda istikrarlı performansı korur.

Yorulma Direnci: Döngüsel yüklere ve titreşime karşı iyi bir direnç sunar.

Elektrik İzolasyonu: Elektrik ve elektronik alanlarda kullanıma uygun, mükemmel bir elektrik yalıtım malzemesidir.

Temel Avantajlar

Bunlar PP'nin altı ana avantajıdır.

1. Hafif ve yüksek mukavemetli: Yoğunluğu sadece 0,89-0,92 g/cm³'tür, ancak mükemmel mekanik özelliklere sahiptir. Mukavemeti, sertliği ve sertliği düşük basınçlı polietilenden daha üstündür, bu da onu otomotiv parçaları ve ev aletleri muhafazaları gibi hafif ürünlerin üretimi için uygun hale getirir.

2. Kimyasal korozyon direnci: Asit, alkali, tuz ve 80°C'nin altındaki çoğu organik çözücüye dayanabilir ve kimyasal kaplar, boru hatları ve tıbbi malzemeler için uygundur.

3. Üstün ısı direnci: Erime noktası 164-176°C'dir ve kısa süreli kullanım sıcaklığı 100°C'ye ulaşabilir. Yüksek sıcaklık direnci onu mikrodalga fırın kapları, otomobil motor parçaları vb. için uygun hale getirir.

4. Mükemmel elektrik yalıtımı: Yüksek frekanslı yalıtım performansı sabittir ve nemden etkilenmez ve elektrik muhafazalarında ve yalıtım bileşenlerinde yaygın olarak kullanılır.

5. Mükemmel işleme performansı: yarı saydamlık, yüksek kristallik ve kolay kalıplama özellikleri, enjeksiyon kalıplama, ekstrüzyon ve diğer işlemleri destekler, filmler, elyaf ürünler ve karmaşık özel şekilli parçalar üretebilir

6. Çevre dostu ve geri dönüştürülebilir: Malzeme geri dönüştürülebilir, bu da sürdürülebilir kalkınma ihtiyaçlarını karşılar ve ambalaj ve otomotiv endüstrilerinde yaygın olarak kullanılır.

Yaygın Uygulamalar

PP'nin beş yaygın uygulaması aşağıdaki gibidir:

1.Dokuma ürünlerPlastik dokuma torbalar, brandalar ve halatlar gibi ürünler çoğunlukla tahıl, gübre ve çimento paketlemek için kullanılır.

2.Enjeksiyon kalıplı ürünler: ağırlıklı olarak küçük ev aletlerinde, günlük ihtiyaçlarda, oyuncaklarda, çamaşır makinelerinde, otomobillerde ve ciro kutularında kullanılır.

3.Film ürünleriBOPP, CPP, genel ambalaj filmleri ve mikro gözenekli filmler vb. dahil olmak üzere ambalajlama, elektrik mühendisliği, elektronik aletler, bantlar, etiket filmleri, filmler, kompozitler ve diğer birçok alanda yaygın olarak kullanılmaktadır.

4.Elyaf ürünleri: Polipropilen elyaf, dekorasyon, endüstri ve giyim gibi üç ana alanda giderek daha fazla kullanılmaktadır ve ikinci en büyük sentetik elyaf çeşidi haline gelmiştir.

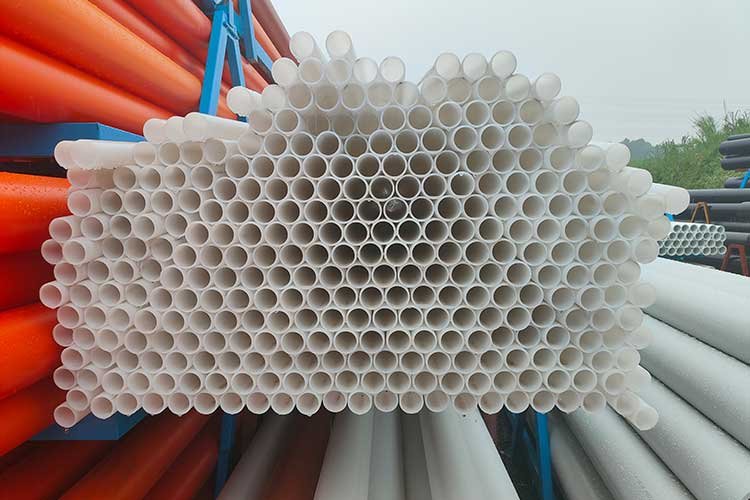

5.Borular: pp borular yüksek sıcaklıklara dayanıklıdır, kolay bağlanabilir (sıcak kaynak, elektrik kaynağı, boru bağlantı parçası bağlantısı) ve geri dönüştürülebilir. Genel olarak bina su tedarik sistemlerinde, ısıtma sistemlerinde, tarım arazisi su tedarik sistemlerinde ve kimyasal boru hattı sistemlerinde kullanılırlar.

Sonuç

Genel olarak PP, uygun kimyasal özellikleriyle bilinir ve bu da onu özellikle boru oluşturmak için çok uygun hale getirir. Bu malzemenin özellikleri onu borular, elyaf ürünler ve genel imalat alanındaki uygulamalar için oldukça cazip kılmaktadır. Ayrıca, maliyet etkinliği ve uyarlanabilirliği onu geniş bir endüstri yelpazesinde oldukça cazip kılmaktadır. Plastik veya imalat endüstrisindeyseniz, PP güvenilir ve çok yönlü bir malzeme çözümü sunar.