1 Hdpe Pipe

Send Your Inquiry Today

1 Hdpe Pipe Manufacturer

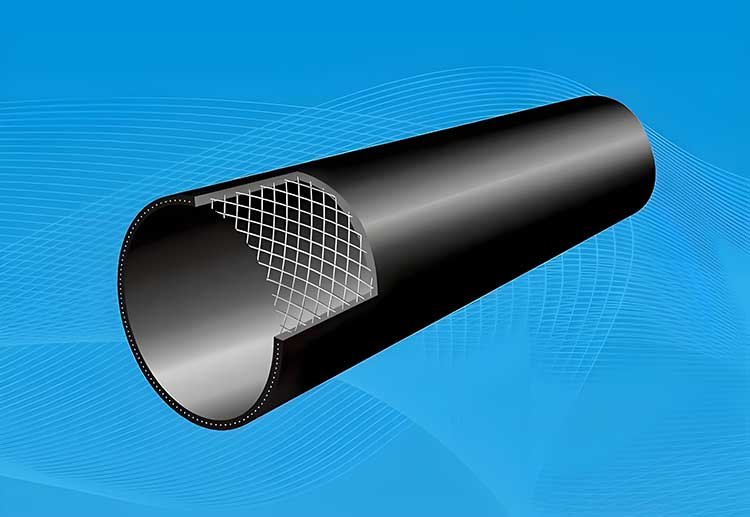

1 HDPE pipe is made of high-density polyethylene (HDPE) through extrusion molding process, with a nominal diameter of about 25.4 mm. The pipe has the characteristics of HDPE material, such as corrosion resistance, wear resistance, and environmental stress cracking resistance, and has high strength and good flexibility. At the same time, the inner wall is smooth, the fluid transmission resistance is small, and the weight is light.

1 HDPE Pipe Features

1 Hdpe Pipe Application Fields

1 HDPE pipe is widely used in many fields due to its excellent performance:

In the household water supply and drainage system

It can be used as a branch pipe for hot and cold water, and ensures the health and safety of water use with its corrosion resistance and non-toxic and environmentally friendly characteristics;

Small garden and home garden irrigation

1 HDPE pipe can accurately transport water, and its flexibility facilitates the laying of complex irrigation lines to meet personalized irrigation needs;

In the field of communications

1 HDPE tubes can be used as micro cable protection sleeves for protection inside buildings or short-distance communication lines, preventing cables from mechanical damage and environmental erosion, and building a solid barrier for the stable transmission of communication signals.

Construction and Installation Specifications

Burial requirements

Minimum cover soil thickness: ≥0.9m under the roadway; ≥0.75m under the sidewalk; ≥0.6m under the green belt.

Trench width: generally the nominal diameter of the pipeline (D) + 0.3-0.5 meters.

Connection method:

Hot-melt connection: suitable for connecting straight pipes and pipe fittings, the temperature is controlled at 210±10℃.

Electric fusion connection: suitable for narrow spaces (such as pipeline wells)

Construction precautions:

Avoid mechanical damage to the pipeline, and handle it with care during transportation and installation.

Pay attention to anti-freezing during winter construction, and drain water after pressure testing to prevent freezing cracks.

The water pressure test pressure is 1.5 times the design pressure.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…