12 Hdpe Pipe

Send Your Inquiry Today

12 Hdpe Pipe Manufacturer

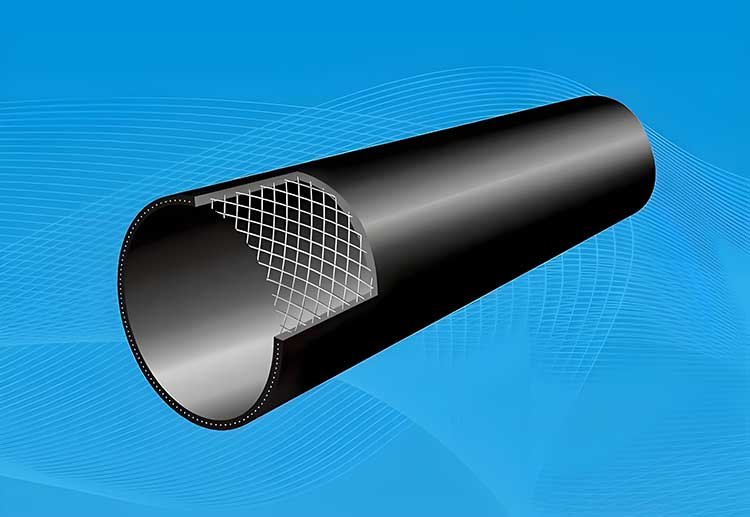

12 HDPE pipe is a high-performance plastic pipe that has become a substitute for traditional metal pipes and concrete pipes due to its excellent physical and chemical properties.

12 HDPE Pipe Features

Mechanical Properties

High tensile strength, impact resistance (drop hammer impact test ≤10% damage at 23°C), ring stiffness ≥8kN/m² (for drainage pipes), adaptable to foundation settlement;

Chemical Properties

Acid-resistant (pH 2~13), alkali-resistant, and salt solution-resistant, it does not react with most chemicals, and is superior to cast iron and steel pipes;

Fluid Performance

The inner wall is smooth (roughness k=0.009mm), the hydraulic friction is small, the flow rate is 30% higher than that of concrete pipes under the same pipe diameter, and it is not easy to scale;

12 Hdpe Pipe Application Fields

12 HDPE pipe is widely used in many fields due to its excellent performance:

Municipal engineering:

Urban water supply and drainage network, integrated pipeline corridor laying;

Water conservancy projects:

Farmland irrigation, reservoir water transfer, river management;

Industrial field:

Material transportation in chemical, pharmaceutical and food factories;

Environmental protection projects:

Leachate collection from landfills, pipe systems for sewage treatment plants.

Connection and Installation Points

- When hot-melt butt welding: the heating temperature (usually 190-230℃) and heating time (adjusted according to the wall thickness of the pipe, the heating time for a 12-inch pipe is about 5-8 minutes) must be strictly controlled. The pipe must not be moved during the cooling process to avoid cracking of the interface.

- When making electric fusion connection: a special electric fusion machine must be used and operated according to the specified parameters (voltage, time). After the connection is completed, it must be cooled naturally for ≥30 minutes. No external force is allowed during the cooling period.

- When crossing special areas such as roads and rivers, a protective casing must be added. The inner diameter of the casing should be 100-200 mm larger than the outer diameter of the HDPE pipe, and both ends should be sealed to prevent mud and sand from seeping in.

- When conveying media containing solid particles, the particle size must be controlled to ≤5 mm and the concentration must be ≤10% to avoid long-term erosion and pipe wear.

- After the pipeline is installed and passes the water pressure test, it should be backfilled in time. The backfill material must be fine soil or medium-coarse sand with a particle size of ≤5 mm. It is strictly forbidden to use hard objects such as stones and bricks.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…