2 Hdpe Pipe

2 The inner wall of the HDPE pipe is smooth, and the fluid transmission resistance is small, which can effectively improve the transmission efficiency. It is also light in weight and easy to install. It is often connected through hot melt, electric melt and other connection methods to ensure that the interface is firmly sealed. It is suitable for small water supply and drainage, landscape irrigation, and communication cable protection engineering fields.

Send Your Inquiry Today

2 Hdpe Pipe Manufacturer

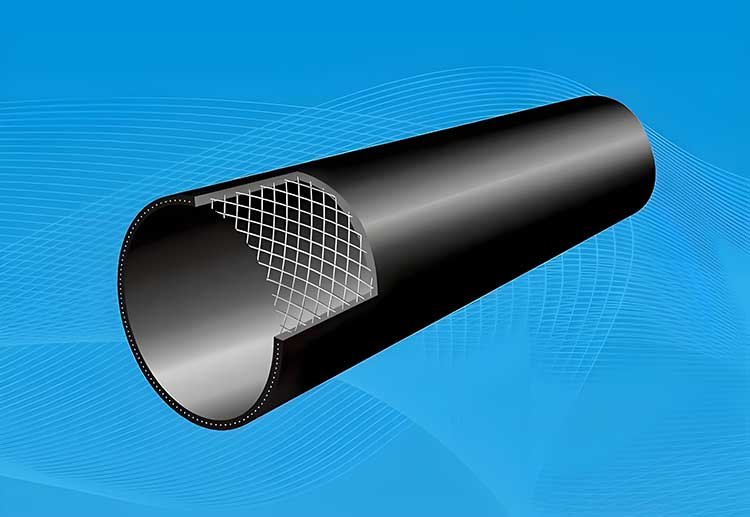

2 HDPE pipe is made of high-density polyethylene as the main raw material through extrusion molding process, and its nominal diameter is about 50.8 mm. It gives full play to the characteristics of HDPE material, has good corrosion resistance, and can resist the erosion of various acids, alkalis, salt solutions and chemical substances; at the same time, it has high strength and high toughness, can withstand certain pressure and external impact, and is not easy to deform and rupture.

2 HDPE Pipe Features

Physical Properties

Light weight: HDPE pipes have a low density. Compared with metal pipes of the same length and diameter, such as steel pipes and cast iron pipes, 2 HDPE pipes are much lighter, making them easier to carry and install, reducing the manpower and equipment costs during the construction process.

Good flexibility: It has good flexibility and can adapt to a certain degree of deformation caused by ground settlement, soil movement and earthquake. 2 HDPE pipe can bend within a certain range without breaking, which can reduce the use of pipe fittings and reduce installation costs.

Strong wear resistance: The polymer component makes the HDPE pipe highly wear-resistant. The wear resistance of 2-inch HDPE pipe even exceeds that of most metals. In the transportation of some fluids containing solid particles, such as mud and slurry, it can maintain a good service life and reduce the wear and replacement frequency of the pipe.

Chemical Properties

Good corrosion resistance: HDPE pipes have good corrosion resistance to most acids, alkalis, salt solutions and organic solvents. 2 HDPE pipes can be used to transport various corrosive media or be buried in corrosive soil environments. They will not be damaged by chemical corrosion, which extends the service life of the pipes.

Strong aging resistance: HDPE pipes containing 2%-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years. Under normal use conditions, 2 HDPE pipes are not prone to performance degradation due to aging even if they are exposed to sunlight or harsh natural environments for a long time.

Mechanical Properties

Strong impact resistance: The special structure makes it have high mechanical strength and ring stiffness. The 2 HDPE pipe can more effectively withstand strong impacts. It is used in earthquake-prone areas or places susceptible to external impacts, and has high safety.

Good stress cracking resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance. The environmental stress cracking resistance of 2 HDPE pipe is also very outstanding. It can withstand certain tensile, compressive and bending stresses without cracking.

Construction Performance

Reliable connection: 2 HDPE pipes are usually connected by electric hot-melt or hot-melt butt welding. The strength of the joint is higher than that of the pipe body, which can ensure the sealing and stability of the connection and reduce the risk of leakage.

Various construction methods: In addition to the traditional excavation method, non-excavation techniques such as pipe jacking, directional drilling, liner, and split pipe can also be used for construction. For some places where large-scale excavation is not allowed, such as urban roads, river crossings, etc.

2 Hdpe Pipe Application Fields

2 HDPE pipe is widely used in many fields due to its excellent performance:

Municipal water supply and drainage:

Used in secondary water supply pipelines in urban communities and towns, providing residents with clean domestic water. Its hygiene and corrosion resistance can ensure water quality safety.

Cable protection sleeve:

As a protective sleeve for communication optical cables and power cables, it is buried underground or laid overhead to protect the cables from external mechanical damage, soil corrosion and humid environment. The 2-inch diameter can accommodate multiple cables for easy threading and maintenance.

Industrial fluid transportation:

In chemical enterprises, corrosive media such as acid, alkaline solution, industrial wastewater, etc. are transported, and its excellent chemical corrosion resistance is used to reduce the frequency of pipeline maintenance and replacement.

Water conservancy facilities:

Alternative pipelines for small canals and drainage ditches can be laid through trenchless technology during river regulation and farmland water conservancy renovation to reduce damage to cultivated land.

Trenchless construction scenarios:

The cable is laid under urban roads, railways, and rivers using trenchless technologies such as directional drilling to reduce interference with traffic and the environment. It is suitable for laying cables around communication base stations and substations.

2 HDPE pipe has moderate diameter and excellent comprehensive performance, making it particularly suitable for small and medium flow transportation, space-constrained scenarios and cost-sensitive projects. Its corrosion resistance, flexibility and ease of construction make it an ideal choice in civil, industrial, environmental protection and other fields.

Construction and Installation Specifications

- Connection method specifications

Hot-melt butt welding / electric hot-melt welding:

Before welding, the port must be cleaned to ensure that the end surface is flat (misalignment ≤ 10% wall thickness), the heating temperature is controlled at 210±10℃, and the cooling time must be sufficient (such as about 15 minutes for a 2-inch pipe) to avoid stress when it is not solidified.

For electric hot-melt welding, a special welding machine must be used, and the voltage and time must be set according to the manufacturer’s parameters. After connection, check whether there is molten material overflowing from the joint to avoid false connection. - Temperature range control

The long-term temperature resistance of HDPE pipe is ≤50℃ (short-term ≤70℃), and it cannot be used for high-temperature medium (such as steam) transportation. If used in geothermal system, it is necessary to confirm that the water temperature does not exceed 50℃, and antioxidants (such as carbon black content ≥2.5%) need to be added.

In low temperature environment (below -20℃), the toughness of the pipe decreases, and violent impact should be avoided during transportation and installation. Insulation measures can be used to prevent freezing and cracking. - Note for trenchless construction: During directional drilling, the pull-back force must be calculated (the pull-back force for a 2-inch pipe is usually ≤5kN) to avoid deformation of the pipe due to excessive tension. The entry angle should be controlled at 8°-15°.

The key to safe use of 2 HDPE pipes is to avoid stress, control temperature, and ensure connection reliability. Before construction, it is necessary to select appropriate specifications based on medium characteristics and environmental conditions, install them strictly according to specifications, and perform regular maintenance in the later stage to give full play to their corrosion resistance and flexibility advantages and avoid failures caused by improper operation.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…