8 Hdpe Pipe

Send Your Inquiry Today

8 Hdpe Pipe Manufacturer

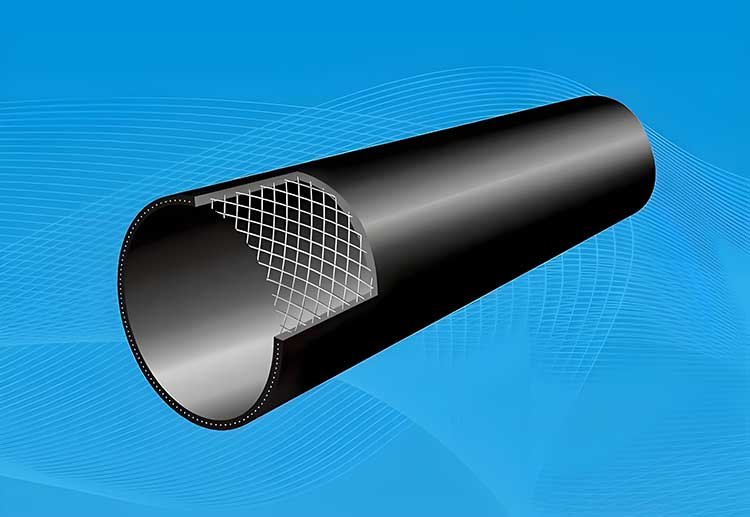

8 HDPE pipe is a high-performance plastic pipe that has become a substitute for traditional metal pipes and concrete pipes due to its excellent physical and chemical properties.

8 HDPE Pipe Features

High strength and toughness

The tensile strength of the pipe is ≥24MPa, the elongation at break is ≥350%, and it has excellent impact resistance. It remains flexible in low temperature environments (-40℃) and is not prone to brittle cracks, making it suitable for laying in complex geological conditions.

Chemical corrosion resistance

It has good tolerance to acid, alkali, salt solution and most organic solvents, and does not require anti-corrosion treatment. It can be used to transport corrosive media such as chemical wastewater and industrial waste liquid, and its service life far exceeds that of metal pipes.

Aging and weather resistance

After adding anti-ultraviolet (UV) and antioxidant additives, it can resist long-term ultraviolet radiation when exposed to the outside; the normal operating temperature range is -40℃~60℃, and the short-term temperature resistance can reach 70℃.

8 Hdpe Pipe Application Fields

8 HDPE pipe is widely used in many fields due to its excellent performance:

Municipal engineering:

Urban water supply and drainage pipelines, rainwater collection systems, and sewage pipe networks.

Industrial field:

Chemical liquid transportation, mine tailings pipelines, power plant circulating water systems.

Agriculture and Water Conservancy:

Large-scale irrigation pipe networks, reservoir water pipelines, and farmland drainage systems.

Special environment:

buried pipelines in coastal areas (anti-salt spray corrosion), high water level areas (good anti-floating performance).

Connection and Installation Points

- Butt fusion: suitable for connecting pipes of the same specification, heating temperature 210±10℃, cooling time adjusted according to the pipe diameter (8-inch pipe cooling about 60-90 minutes), no risk of leakage at the interface.

- Electric fusion connection: The electric fusion pipe is fused by electricity, which is easy to operate and suitable for quick installation on site, especially for maintenance scenarios.

- Flange connection: used for transition connection with metal equipment or pipelines, with reliable sealing.

- Laying and backfilling requirements:When laying pipes, avoid excessive bending (allowable curvature radius ≥ 30D, i.e. 6 meters). If turning is required, special elbows or natural bending should be used. Forced bending is strictly prohibited.

- Backfill is divided into three layers: 300mm from the bottom of the pipe to the top of the pipe is filled with medium-coarse sand (compaction coefficient ≥ 93%), 300-500mm is filled with plain soil (remove stones, compaction coefficient ≥ 90%), and above 500mm is backfilled as usual. It is strictly prohibited to use frozen soil, construction waste or crushed stone for direct landfill.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…