24 Hdpe Pipe

Send Your Inquiry Today

24 Hdpe Pipe Manufacturer

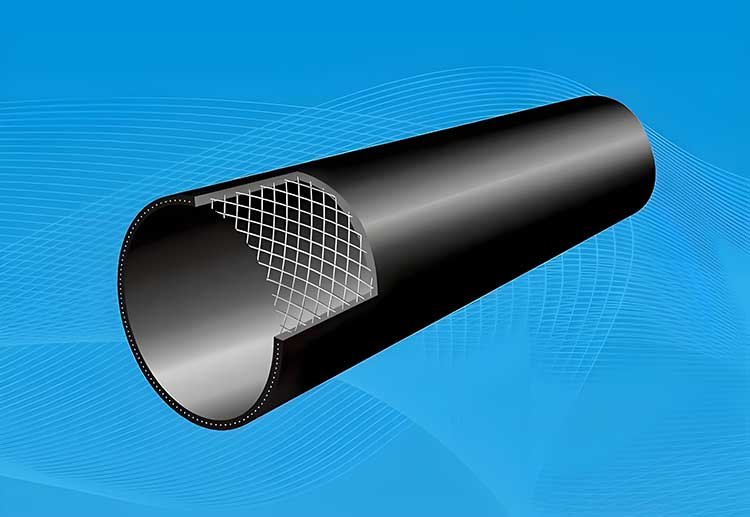

24 HDPE pipe is a large diameter high-density polyethylene pipe. It is a highly crystalline, non-polar thermoplastic resin with excellent resistance to most domestic and industrial chemicals, non-hygroscopic and good water vapor resistance.

24 HDPE Pipe Features

Excellent corrosion resistance:

It is resistant to corrosion from a variety of chemical media and has no electrochemical corrosion. It is suitable for conveying media with certain corrosiveness, such as certain industrial wastewater, and is widely used in the chemical industry, sewage treatment and other fields.

Good flexibility

It has high impact strength, is resistant to strong earthquakes and distortion, and can maintain good stability and integrity even in areas with complex geological conditions, such as earthquake-prone areas or areas prone to ground subsidence, reducing the risk of pipeline rupture and leakage.

Long service life

Under normal conditions of use, the service life can reach more than 50 years, which has good long-term economic performance, can reduce the frequency of pipeline replacement and maintenance, and reduce overall costs.

24 Hdpe Pipe Application Fields

24 HDPE pipe is widely used in many fields due to its excellent performance:

Municipal engineering:

It is used in the main water pipeline or secondary water supply network in the city to transport drinking water, recycled water, etc. to meet the water needs of residents and industry. Its corrosion resistance and smooth inner wall can avoid water pollution and reduce water transportation energy consumption.

Water Conservancy Project:

It is used for inter-regional water transfer, reservoir water pipelines, etc., such as the South-to-North Water Transfer Project, irrigation area trunk canals, etc. The 24-inch large diameter can meet the needs of long-distance and large-flow water transfer, and has strong impact resistance and adapts to terrain undulations.

Agricultural irrigation:

As the main irrigation pipeline for farmland, it connects reservoirs, pumping stations and field pipe networks to transport irrigation water. Its light weight and convenient installation can reduce the amount of farmland excavation and the damage to cultivated land caused by construction. At the same time, its aging resistance makes it suitable for long-term outdoor use.

Industrial field:

It can transport acid and alkali solutions, industrial wastewater, and corrosive chemical raw materials (such as hydrochloric acid, sodium hydroxide, etc.), avoiding corrosion of metal pipes and extending the life of the system.

Special scenes of trenchless construction:

When using non-excavation technologies such as pipe jacking and directional drilling to cross roads, rivers, and railways, 24-inch HDPE pipes can reduce construction difficulty and damage to the surrounding environment due to their good flexibility and light weight, and are especially suitable for pipeline renewal in urban built-up areas.

24 HDPE pipes are irreplaceable in scenarios that require large flow, adaptability to complex environments, or high environmental requirements due to their large diameter, high toughness, corrosion resistance, and flexible construction. They are especially suitable for the construction of trunk pipe networks in the fields of municipal administration, water conservancy, and industry.

Connection and Installation Points

- Electric fusion connection: Make sure the electric fusion sleeve fits tightly to the pipe. Check the melting state after connection to make sure there is no false welding.

- Temperature control: Heating plate temperature 210±10℃, heating time adjusted according to pipe thickness

- Mechanical connection (such as clamp type): suitable for temporary repair or where hot melting is not possible, and the sealing performance needs to be checked regularly

- Crossing roads or rivers: Set up casing or bridge to cross, and the length of the casing must exceed the width of the road by 1-2 meters.

- High temperature environment: Avoid prolonged exposure to the sun. If necessary, cover with a sunshade net or shorten the construction time.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…