The weight per meter of PE pipe is not only a direct reflection of material usage, but also a key indicator of the pipe’s pressure-bearing capacity and construction difficulty. But how can it be accurately calculated using parameters such as outer diameter and wall thickness? This article will break down the calculation formula for the weight per meter of PE pipe from the perspectives of material density and geometric models.

What is the concept of weight in meters?

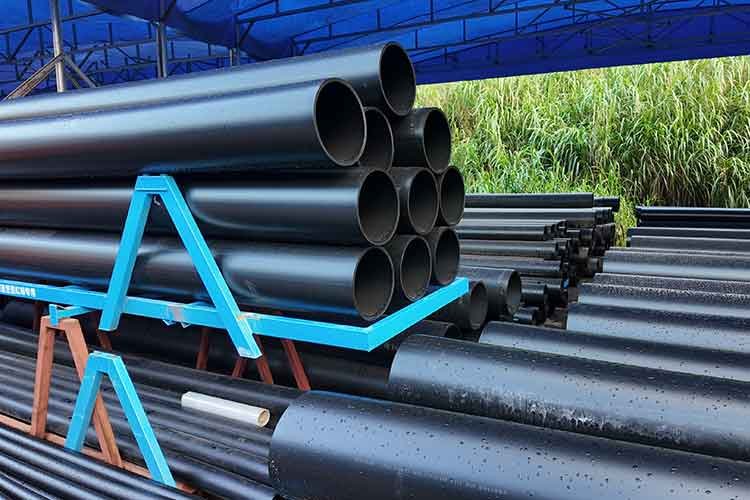

The weight per meter of Tubo de PE refers to the mass or weight of polyethylene (PE) pipe per meter of length, usually expressed in kilograms per meter (kg/m). Weight per meter measures the relationship between the weight of the pipe material and its length, and it has significant applications in engineering design, construction, load calculation, transportation, and material selection.

What factors affect the weight of a meter?

Pipe diameter and wall thickness

Larger diameter and thicker wall thickness PE pipes will have a higher weight per meter because more material is used in their manufacture.

Pipe type

Different types of PE pipes, such as PE80 and PE100, have different densities and mechanical properties, so their weight per meter will also vary.

Material density

The density of PE pipe material is an important factor in calculating the weight per meter. Different types of PE have different densities, which affects the weight per meter of the pipe.

How is the weight per meter calculated?

—1) Determine the density of the PE pipe material. The density of HDPE is typically between 0.93 and 0.97 g/cm³.

—2) Determine the diameter and wall thickness of the PE pipe. Generally, the average of the outer diameter and wall thickness is used for calculation.

—3) Calculate the weight per meter of the PE pipe using the formula:

Weight per meter (kg/m) = (Outer diameter – Wall thickness) * Wall thickness * 3.14 * Density / 1000

For example:

A PE pipe with an outer diameter of 110mm and a wall thickness of 4.2mm,

its weight per meter is calculated as follows:

(110 – 4.2) x 4.2 x 3.14 x 0.97 / 1000 = 1.35 kg

Note: The theoretical calculation formula may deviate slightly from the actual result.

The importance of meter weight

Weight per meter is a very useful parameter in pipe design, manufacturing, installation, and use, and can be used in the following aspects:

Engineering design and planning

Weight-per-meter data can be used in engineering design to help engineers calculate the total weight and stress of a piping system. This helps determine the required support structures and supports for the pipeline, ensuring that the pipeline can withstand the expected weight and load during operation.

Construction estimate

Weight per meter is used for resource estimation during the construction phase, helping to estimate material requirements, transportation costs, and human resources. Knowing the weight of each meter of pipe allows for better planning of material transportation and installation processes.

Transportation and installation

Weight per meter helps determine the appropriate equipment and methods for the safe and efficient transport and installation of pipelines. It can be used to select suitable lifting equipment, transport vehicles, and to ensure the safety of construction personnel.

Pipe support and fixation

Weight per meter is crucial for the design and installation of piping support and securing systems. This helps ensure that the piping does not experience excessive deflection or stress during operation, thus guaranteeing system stability and safety.

Material cost estimation

Weight per meter data is used to calculate the cost of pipe materials, which can help with budget estimation and project bidding. Based on the pipe length and material cost, the total cost of the required materials can be calculated.

Quality control and inspection

Weight per meter data can be used for quality control and inspection to ensure that the manufactured pipes meet specifications. Comparing the actual weight per meter with the expected weight per meter can be used to detect manufacturing deviations.

Conclusión

Because weight per meter data typically varies depending on factors such as manufacturer, pipe specifications, material properties, and manufacturing processes, there is no single standard to define an exact weight per meter.