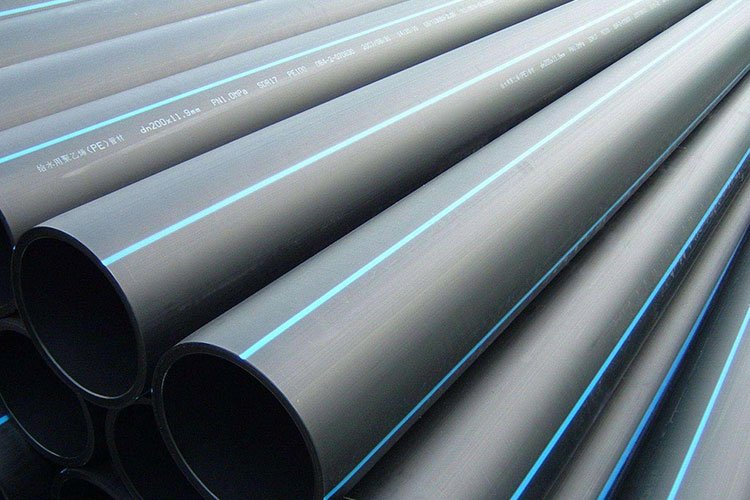

What is Polyethylene Pipe?

Polyethylene pipe is a thermoplastic plastic pipe system made of polyethylene resin as the main raw material.

Core performance characteristics of polyethylene pipes

- Strong corrosion resistance: Polyethylene material has good resistance to most chemicals, including acids, alkalis, salts and many organic solvents, so it is very suitable for conveying different types of fluids.

- Good flexibility: Compared with pipes made of other materials, polyethylene pipes have better flexibility and bendability, which makes it easier to install in complex terrain.

- Good impact resistance: Polyethylene material has good impact resistance and can maintain high toughness even in low temperature environments.

- Light weight: Compared with metal pipes, polyethylene pipes are lighter and easier to transport and install.

- Long life: Polyethylene pipes are designed to last for more than 50 years and require little maintenance under proper use conditions.

Polyethylene pipe application areas

- Water supply system: Due to its non-toxic and corrosion-resistant characteristics, it is often used for drinking water transmission.

- Drainage system: can be used for rainwater collection, construction of sewer and wastewater treatment systems.

- Power engineering: protective casing for wires and cables, etc.

- Industrial field: Pipeline systems for transporting various corrosive media, chemical raw materials, etc. in chemical, petroleum, pharmaceutical and other industries.

- Construction projects: water supply and drainage pipes inside buildings, as well as floor heating pipes, etc.

Polyethylene pipe production process

Generally, the extrusion molding process is adopted. After the polyethylene raw material is heated and melted, it is extruded into a tube through an extruder, and then cooled and sized to make a polyethylene pipe. In addition, according to different usage requirements, injection molding, blow molding and other processes can also be used to produce polyethylene pipe accessories.

Advantages of using polyethylene pipes

- Low cost: The production process is relatively simple, the raw material cost is low, and the service life is long and the maintenance cost is low, so the overall cost is lower than traditional metal pipes.

- Good environmental protection: Polyethylene pipes can be recycled and reused without causing pollution to the environment, and meet environmental protection requirements.

- High construction efficiency: light weight, easy connection, fast construction speed, and can shorten the project period.

Polyethylene pipes are made of polyethylene materials and are widely used in many fields due to their excellent corrosion resistance, good flexibility, light weight and excellent impact resistance. They are used in water supply and drainage systems, agricultural irrigation and industrial purposes, especially when they need to resist chemical corrosion or lay pipes in complex terrain conditions.