4 Hdpe Pipe

Send Your Inquiry Today

4 Hdpe Pipe Manufacturer

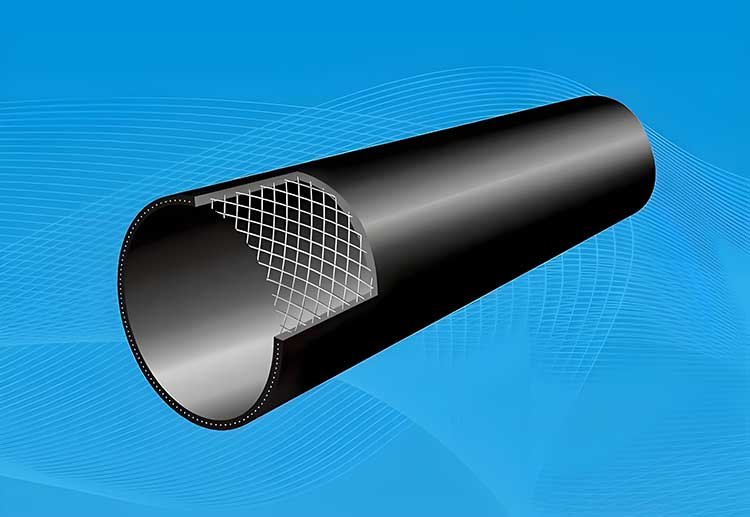

4 HDPE pipe is a high-performance plastic pipe that has become a substitute for traditional metal pipes and concrete pipes due to its excellent physical and chemical properties.

4 HDPE Pipe Features

Physical Properties

Lightweight: The density is about 0.94-0.96g/cm³, and the weight is only 1/7 of the steel pipe of the same diameter. The transportation and lifting costs are reduced, which is suitable for large-scale engineering construction.

Flexibility: The bending radius can be ≥30 times the pipe diameter (e.g. the bending radius of a 110mm pipe is ≥3.3m), which can adapt to complex terrain and reduce the amount of pipes used.

Chemical Properties

Corrosion resistance: Acid and alkali resistant (pH3-11), soil electrochemical corrosion resistant, no anti-corrosion coating required, service life can reach more than 50 years in coastal high-salt environment or industrial pollution area.

Low permeability: The molecular structure is dense, and the gas permeability is less than 0.005cm³/(m・h), which is suitable for the transportation of gas and chemical media to avoid leakage risks.

Mechanical Properties

High strength: PE100 grade tensile strength ≥26MPa, outstanding internal pressure resistance (SDR11 pipe pressure resistance 1.0MPa, bursting pressure>5.0MPa), excellent external pressure impact resistance (-40℃ drop hammer impact breakage rate<10%).

Thermal Properties

Temperature resistance range: -40℃ to +60℃ for long-term use, short-term resistance to +70℃, suitable for temperate to cold climates, ultraviolet stabilizers need to be added in tropical areas (UV content ≥2.5%).

4 Hdpe Pipe Application Fields

4 HDPE pipe is widely used in many fields due to its excellent performance:

Water supply network:

As a city trunk pipe or community water supply pipe, it replaces ductile iron pipes and complies with GB/T 13663 sanitary standards, with high water transmission efficiency and no pollution to water quality.

Chemical industry:

Transporting strong acid (such as sulfuric acid), strong alkali (such as sodium hydroxide) solutions, or industrial wastewater;

Drainage system:

Double-wall corrugated pipes (such as SN8 grade) are used for rainwater and sewage discharge. When buried underground, their anti-settling performance is better than that of cement pipes and can withstand a soil cover depth of 3-5m.

Cable protection tube:

Protect high-voltage cables when buried underground, resist soil stress and mechanical damage, and can withstand ground loads of 10t/m².

Mining field:

Slurry conveying pipeline, wear-resistant (wear loss <150mg/1000 times), service life is 2-3 times longer than steel pipe.

Connection and Installation Points

- Hot-melt butt welding: suitable for straight pipe connection, requires the use of a special hot-melt machine (such as a 110mm diameter heating plate with a diameter of 120mm), heating temperature 210±10℃, heat absorption time ≥45 seconds, cooling time ≥40 minutes, and the interface strength is consistent with the pipe body.

- Electric fusion connection: used for pipe fittings (such as tees, elbows) or connections with metal parts. It is necessary to use electric fusion pipe fittings with barcodes, scan the parameters through the electric fusion machine (such as voltage 220V, heating time 150 seconds), and avoid stress during cooling.

- Flange connection: used when connecting with metal equipment, with HDPE flange root and rubber sealing ring, bolt torque is controlled at 80-120N・m to prevent leakage due to eccentricity.

- Construction Note: When burying underground, a 200mm fine sand cushion layer should be laid at the bottom of the trench to prevent stones from scratching the pipe; the backfill soil particle size should be ≤50mm and compacted layer by layer (compaction coefficient ≥93%); in cold areas, it should be buried deep below the frozen soil layer (such as covering soil ≥1.5m in northern areas).

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…