6 Hdpe Pipe

Send Your Inquiry Today

6 Hdpe Pipe Manufacturer

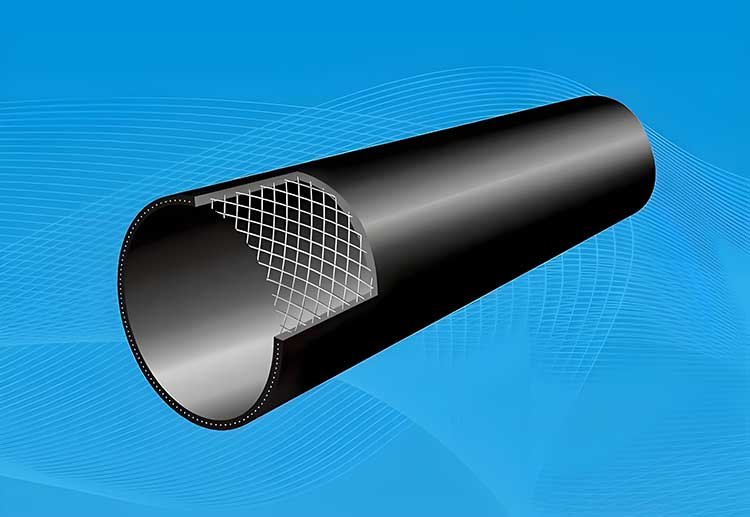

6 HDPE pipe is a high-performance plastic pipe that has become a substitute for traditional metal pipes and concrete pipes due to its excellent physical and chemical properties.

6 HDPE Pipe Features

Strong corrosion resistance

It has good tolerance to acids, alkalis, salt solutions and organic chemicals (such as gasoline and alcohol), and does not require additional anti-corrosion treatment. It is suitable for the transportation of corrosive media such as chemicals, sewage, and gas, reducing maintenance costs.

Anti-aging and weather resistance

After adding anti-ultraviolet (UV) additives, it can resist ultraviolet radiation when exposed to the outside; the performance is stable within the temperature range of -40℃~60℃, it is not easy to crack at low temperatures and not easy to soften at high temperatures (short-term temperature resistance can reach 70℃).

Wear and impact resistance

The friction coefficient of the pipe wall is low (about 0.009-0.01), the resistance is small when conveying fluid, and it is not easy to scale; the impact strength is more than 10 times that of PVC pipes, and it can resist soil settlement or external load impact when buried underground.

6 Hdpe Pipe Application Fields

6 HDPE pipe is widely used in many fields due to its excellent performance:

Municipal engineering:

Urban water supply pipelines (replacing galvanized steel pipes to avoid rust and scaling), rainwater and sewage diversion drainage (resistant to acid and alkali sewage corrosion), gas transmission (buried underground without electrochemical corrosion);

Agricultural water conservancy:

Irrigation main pipelines (anti-ultraviolet additive content ≥ 2.5%, sun protection is required for outdoor use), reservoir water pipelines (water pressure resistant and with few joints);

Industrial field:

Chemical raw material transportation (such as methanol, ethanol), mine tailings discharge (wear-resistant and impact-resistant), seawater desalination pipeline (chloride ion corrosion resistance);

Special scenarios:

Non-excavation construction (directional drilling can be used for pipes with a diameter of ≤200mm to reduce road excavation), geological disaster areas (good flexibility and strong anti-settlement ability).

Connection and Installation Points

- Hot-melt butt welding: ensure that the joint is clean and dry, control the heating temperature at 210±10℃, strictly follow the heating time and pressure according to the pipe specifications (such as the hot-melt time of a 6-inch pipe is about 45-60 seconds), and avoid stress on the joint during the cooling process.

- Electric fusion connection: Use a special electric fusion machine, the insertion depth must reach the marking line, and the power-on parameters are set according to the pipe fitting identification to prevent false welding or over-melting resulting in water leakage.

- Temperature range: The recommended working temperature is -40℃~60℃. The maximum temperature for a short period of time (no more than 24 hours) should not exceed 70℃. Avoid long-term use in high temperature environments (such as transporting hot water) to prevent the strength of the pipe from decreasing.

- Aging protection: Exposed pipes need to be painted with anti-UV paint or wrapped with a sunscreen layer to delay aging; avoid using construction waste when backfilling buried pipes to prevent sharp objects from puncturing the pipes.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…