Mining Pipe

The design and selection of mining pipes must fully consider the special needs of the mining environment to ensure that they can achieve efficient operation and long-term reliability while ensuring safety.

Send Your Inquiry Today

Mining Pipe Supply

Mining pipes are pipeline systems designed and used specifically for the mining and mineral processing industries to transport a variety of fluids or gases, including water, mud, tailings, chemicals, compressed air, etc. These pipelines play a vital role in the mining environment because they must be able to withstand extreme working conditions such as high pressure, high temperature and the influence of corrosive media.

Mining Pipe Main Features

Mining Pipe Material Selection

The material selection for mining pipes depends on the specific application scenario and its requirements. Common materials include but are not limited to:

Polyethylene (PE) and high-density polyethylene (HDPE): widely used due to their excellent chemical resistance and certain flexibility.

Polypropylene (PP): provides good heat resistance and chemical corrosion resistance.

Metal pipes (such as steel pipes): particularly important where higher strength and pressure resistance are required, but anti-corrosion measures may need to be considered.

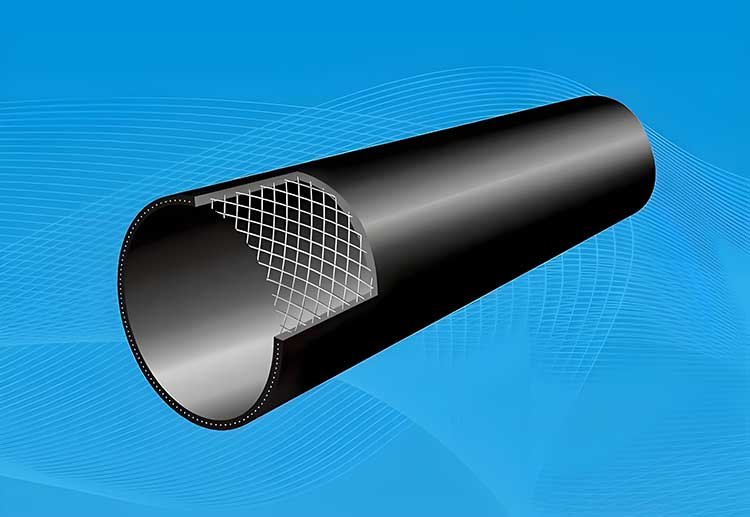

Composites: combine the advantages of multiple materials and aim to improve the durability and functionality of the pipe at the same time.

Applications of JUNTONG Mining Pipe

Hydraulic transport: used to transport slurry or tailings, it is an economical and effective way to move materials over long distances.

Ventilation system: provides necessary fresh air for underground mines and helps to remove harmful gases.

Water supply and drainage: ensure the supply of clean water inside and outside the mine area and effectively manage wastewater discharge.

Chemical transmission: used to handle and transport various chemical reagents during the mineral processing process.

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…