Municipal Pipe

Municipal pipe are usually buried underground (partly overhead) and need to be uniformly designed and laid out according to urban planning. They must have characteristics such as systematicity, concealment, and durability. Their construction quality directly affects the efficiency of urban operations and the quality of life of residents.

Send Your Inquiry Today

Municipal Pipe Supply

Municipal pipe refer to pipeline systems used to transport and discharge various fluids (such as water, sewage, rainwater, gas, etc.) in urban infrastructure construction. Pipeline networks constitute the lifeline of modern cities, supporting the normal operation of cities and the living needs of residents. The design and construction of municipal pipelines must follow strict standards and specifications to ensure their safety, reliability and durability.

Municipal Pipe Main Types

Municipal Pipe Material Selection

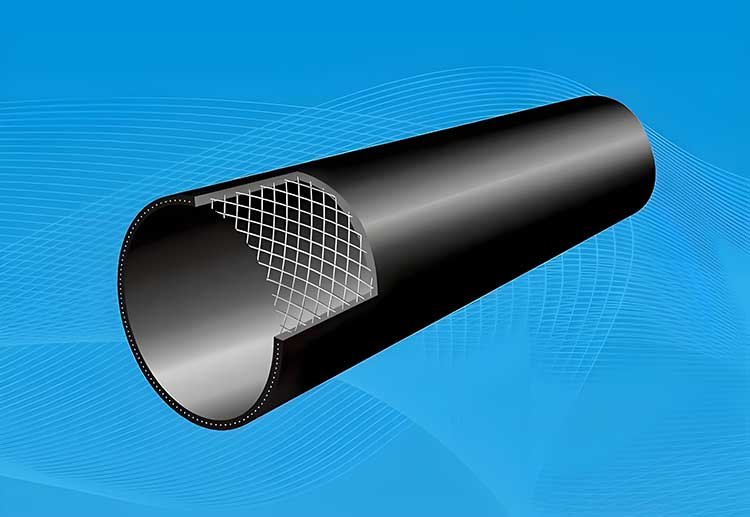

There are various materials for municipal pipelines, the most common ones are polyethylene (PE), polypropylene (PP), etc. Different types of pipeline materials are suitable for different application scenarios. For example, PE and PP pipes are becoming more and more popular in modern municipal engineering due to their excellent corrosion resistance and easy installation; while traditional materials such as cast iron and steel pipes are more often used in occasions with higher requirements for strength and durability.

Key points for municipal pipe construction and maintenance

Construction points

1.Trench excavation: Control the flatness of the base according to the characteristics of the pipe. Soft soil foundation requires laying a sand cushion layer (thickness ≥ 150mm)

2.Pipeline connection: PE pipes are connected by hot melt or electric fusion, and steel pipes are connected by welding or flange to ensure the quality of the interface.

3.Anti-corrosion treatment: The outer anti-corrosion layer of the steel pipe must meet the design standards (such as 3PE coating thickness ≥ 2.9mm).

Maintenance Management

1.Regular inspection: Use CCTV inspection, ultrasonic thickness measurement and other technologies to evaluate the internal condition of the pipeline.

2.Desilting and dredging: Stormwater pipes should be desilted at least once a year, and the desilting cycle of sewage pipes should be determined based on flow rate and water quality.

3.Emergency response: Establish a pipeline network geographic information system (GIS) to quickly locate fault points; reserve emergency supplies (such as plugging materials and pumping equipment).

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…