Hdpe Pipe

HDPE pipe are extremely resistant to most chemicals (such as acids, alkalis, and salts), have good flexibility and impact resistance, can adapt to a certain degree of ground subsidence and deformation, and have excellent seismic performance.

Send Your Inquiry Today

Hdpe Pipe Manufacturer in China

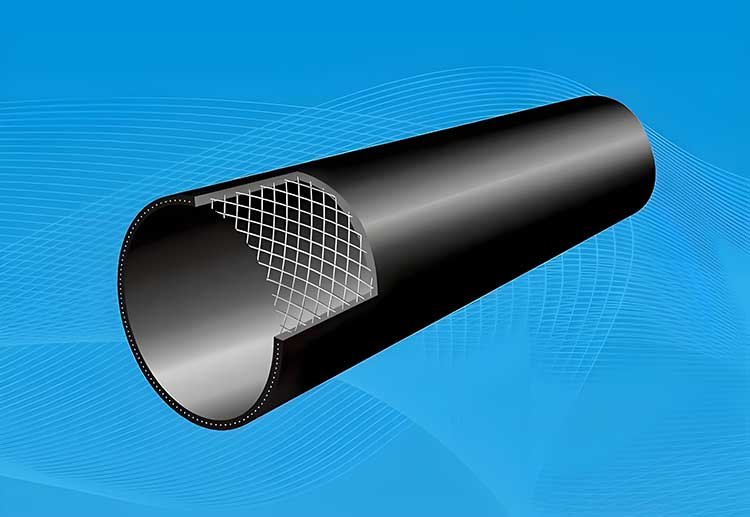

Hdpe pipe is a plastic pipe made of high-density polyethylene (HDPE) resin as the main raw material, through extrusion molding or other processing techniques.

HUALIN Hdpe pipes are usually made by extrusion molding. After the high-density polyethylene resin is heated and melted, it is extruded into pipes through an extruder. During the production process, appropriate additives such as antioxidants, ultraviolet absorbers, etc. can be added according to different usage requirements to improve the performance of the pipe.

Hdpe Pipe

Hdpe Water Supply Pipe

Send Your Inquiry Today

Hdpe Perforated Pipe

Send Your Inquiry Today

HDPE Cable Tube

Send Your Inquiry Today

Hdpe Sewage Pipe

Send Your Inquiry Today

HDPE Siphon

Send Your Inquiry Today

Hdpe Roll Core Pipe

Send Your Inquiry Today

HDPE Pipe Sizes & Specifications

| Specification | SDR11 1.6MPa | SDR13.6 1.25MPa | SDR17 1.0MPa | SDR21 0.8MPa | SDR26 0.6MPa |

| Wall thickness(mm) | |||||

| DN20 | 2.3 | ||||

| DN25 | 2.3 | 2.3 | |||

| DN32 | 3.0 | 2.4 | 2.3 | ||

| DN40 | 3.7 | 3.0 | 2.4 | 2.3 | |

| DN50 | 4.6 | 3.7 | 3.0 | 2.4 | |

| DN63 | 5.8 | 4.7 | 3.8 | 3.0 | 2.5 |

| DN75 | 6.8 | 5.6 | 4.5 | 3.6 | 2.9 |

| DN90 | 8.2 | 6.7 | 5.4 | 4.3 | 3.5 |

| DN110 | 10.0 | 8.1 | 6.6 | 5.3 | 4.2 |

| DN125 | 11.4 | 9.2 | 7.4 | 6.0 | 4.8 |

| DN140 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 |

| DN160 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 |

| DN180 | 16.4 | 13.3 | 10.7 | 6.6 | 6.9 |

| DN200 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 |

| DN225 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 |

| DN250 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 |

| DN280 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 |

| DN315 | 28.6 | 23.2 | 18.7 | 15.0 | 12.1 |

| DN355 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 |

| DN400 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 |

| DN450 | 40.9 | 33.1 | 26.7 | 21.5 | 19.2 |

| DN500 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 |

| DN560 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 |

| DN630 | 57.2 | 46.3 | 37.4 | 30.0 | 24.1 |

Key Features of HUALIN Hdpe Pipe

HDPE pipe is white powder or granular, with a density of 0.940~0.976 g/cm³, a crystallinity of 80%~90%, a softening point of 125~135℃, an operating temperature of up to 100℃, and a short-term upper temperature limit of 120~160℃. Its chemical properties are resistant to acid, alkali and salt corrosion, insoluble in organic solvents at room temperature, but sensitive to strong oxidizing media14; long-term use may lead to performance degradation due to thermal oxidation, and antioxidants need to be added to improve; HDPE pipe has high rigidity, toughness and creep resistance, and its wear resistance and environmental stress cracking resistance are better than low-density polyethylene

Send Your Inquiry Today

Why Choose Our Hdpe Pipe?

hualin pipe hdpe pipe can operate safely within the range of -60~60℃, with no risk of brittle cracking during winter construction, and a short-term temperature resistance upper limit of 120~160℃, suitable for complex climate environments; our high-density polyethylene pipes support traditional excavation and trenchless technology (jacking, directional drilling), adapt to urban transformation and complex terrain requirements, and reduce interference with the surrounding environment. The raw materials they use are non-toxic and harmless, meet environmental protection requirements, and can be recycled and reused; the smooth inner wall reduces water flow resistance and reduces energy consumption

Send Your Inquiry Today

HUALIN Hdpe Pipe Applications Explored

Our Hdpe pipe are widely used in various applications to solve the problems of corrosion and short life of traditional pipes. In the industrial field, they can withstand corrosive fluids such as strong acids, alkalis, and salts (such as chemical wastewater treatment), and replace metal pipes to reduce the risk of leakage. In power and communications, they are used for direct burial or trenchless laying (such as highway power channels), resist soil erosion and chemical corrosion, and their flexibility supports wiring in complex terrains and protects communication lines. In water supply and drainage projects, they can be used for urban tap water supply pipes, drainage pipes, sewage treatment pipes, etc.

FAQ

Related Articles

What is PE Electrofusion Welding?

The most common PE pipe connection methods in pipeline installation include: heat fusion connection, electrofusion…

What is PE Steel Wire Mesh Composite Pipe?

Are you looking for plastics suitable for municipal water supply and drainage? PE steel wire…

Comprehensive Guide to Trenchless PE Pipe Technology

With the acceleration of global urbanization, municipal construction requires the laying and replacement of a…

Why use HDPE pipes in siphon drainage systems?

When it rains, you can hear a terrifying gurgling sound occasionally coming from the drainpipes,…

Pipe Specification Designation – Comprehensive Guide

Pipe specifications are commonly indicated using various methods such as DN, inch, D, Φ, De,…

How to calculate PE pipe wall thickness

PE pipes are widely used in urban water supply and drainage, gas, telecommunications, and power…